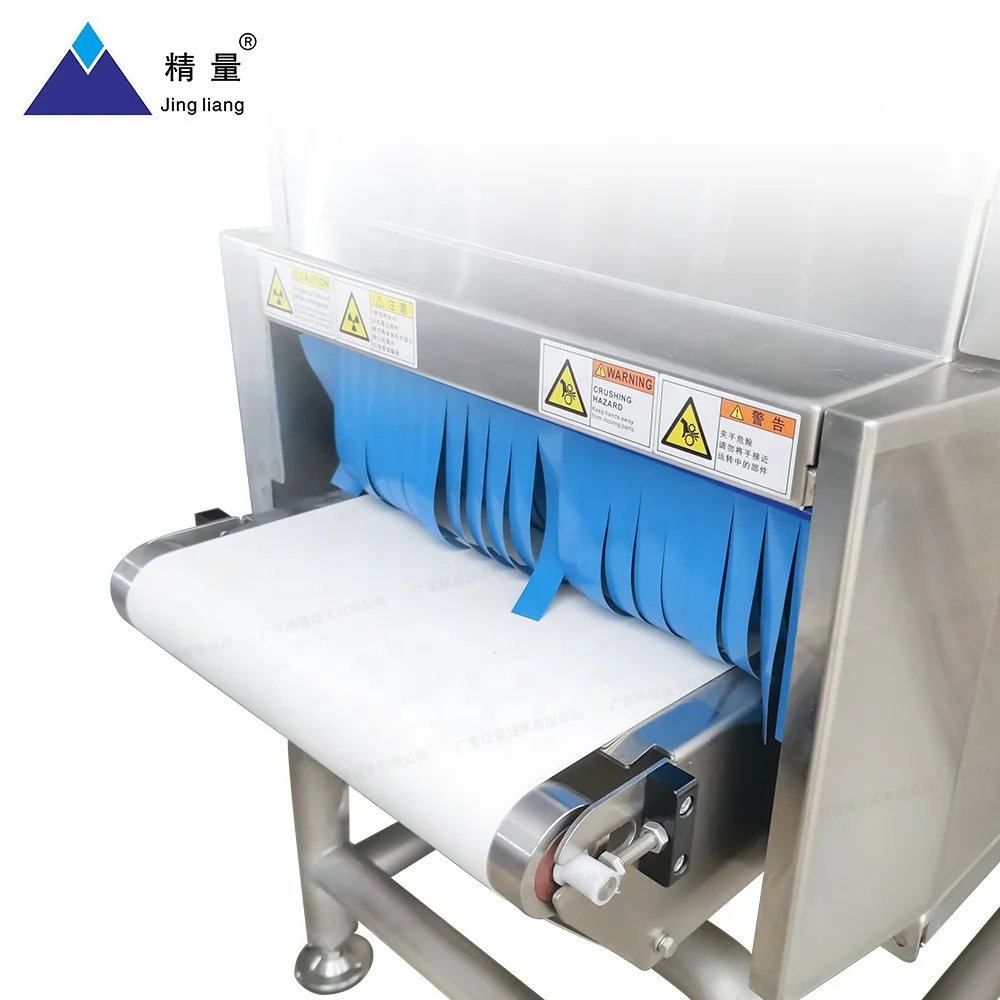

Every X-ray machine is a specialized device that can see through an object. They're commonly used in hospitals to take images of bones, but they can also scan our food! Jing Liang has some really cool x-ray machines that help keep our food safe.

X-ray machines very useful for food checking. They help us ensure the food we consume is safe. Food travelling through an x-ray machine behind the scenes gives us a glimpse of whether or not there is something bad inside that we otherwise wouldn't be able to see with the naked eye.

Data cut off: October 2023. If food passes through an x-ray machine it can spot if there is anything bad in there. Some bad things could be small bits of metal, plastic, or even bugs! They can see these in the x-ray machine and get them out of there before we eat.

You are dedicated to large area where food is manufactured and packed. They are also placed in the food are X-ray inspected to avoid any food that may have passed on to us. Jing Liang’s x-ray machines help food companies inspect their products to ensure they aren’t contaminated with anything that could make us sick.

Using x-ray machines to check food is a lot of good stuff. First, it helps protect us by ensuring that our food is free of toxins. Second, it aids food companies in confirming their products are of good quality and safe. Finally, x-ray machines can be very rapid and screen multiple foods in a short period.

X-Ray inspection, in food processing, is amazing to make sure that we are eating safe food. Jing Liang’s x-ray machines make it simple for food companies to look for bad stuff and remove it; that patch can be removed before the food is packed and shipped out to stores. The approach also helps us be confident that the food we purchase is safe and done with attention to detail.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.