Ensuring that the products we rely on every day is safe is one of the utmost importance. This is where x-ray product inspection comes into play. This type of inspection allows companies such as Jing liang look through products to ensure they are manufactured correctly and that there are no issues. Learn more about x-ray product inspection and why it matters.

X-ray product inspection is crucial in ensuring that the products we use are safe. Jing liang uses x-ray machines to check products for internal issues. This helps them locate missing parts, broken pieces, or objects that shouldn’t be there. Detecting these issues early allows companies like Jing liang to resolve them before their products are delivered to customers. This makes sure that everyone is safe and happy.

X-ray inspection is a useful method to verify that products are manufactured properly. Using x-ray machines, Jing liang is able to determine whether a products components are in their correct place and whether they are the appropriate size. It allows them to identify pitfalls that occur when developing products. Companies such as Jing liang can check out these mistakes in order to ensure that the products they release are high quality and fulfill their function.

Product X-ray inspection also helps Jing liang ensure that the products they manufacture are safe for use. They can see inside products with x-ray machines to inspect them for dangerous objects or materials. This helps them ensure that their products comply with safety regulations and will not harm anyone who uses them. Some companies like Jing liang are able to ensure that their customers can trust the products they buy by making safety the top priority.

Why Should You Consider x-ray product inspection? By identifying problems at an early stage, companies like Jing liang can save time and money by correcting issues before products are dispatched. The quality and safety of these products can also be ensured by companies with the use of X-ray inspection. This allows them to build a reputation and ensure repeat customers. Hence, x-ray product inspection is an excellent way for companies like Jing liang to ensure that the products they manufacture are of the highest caliber possible.

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.

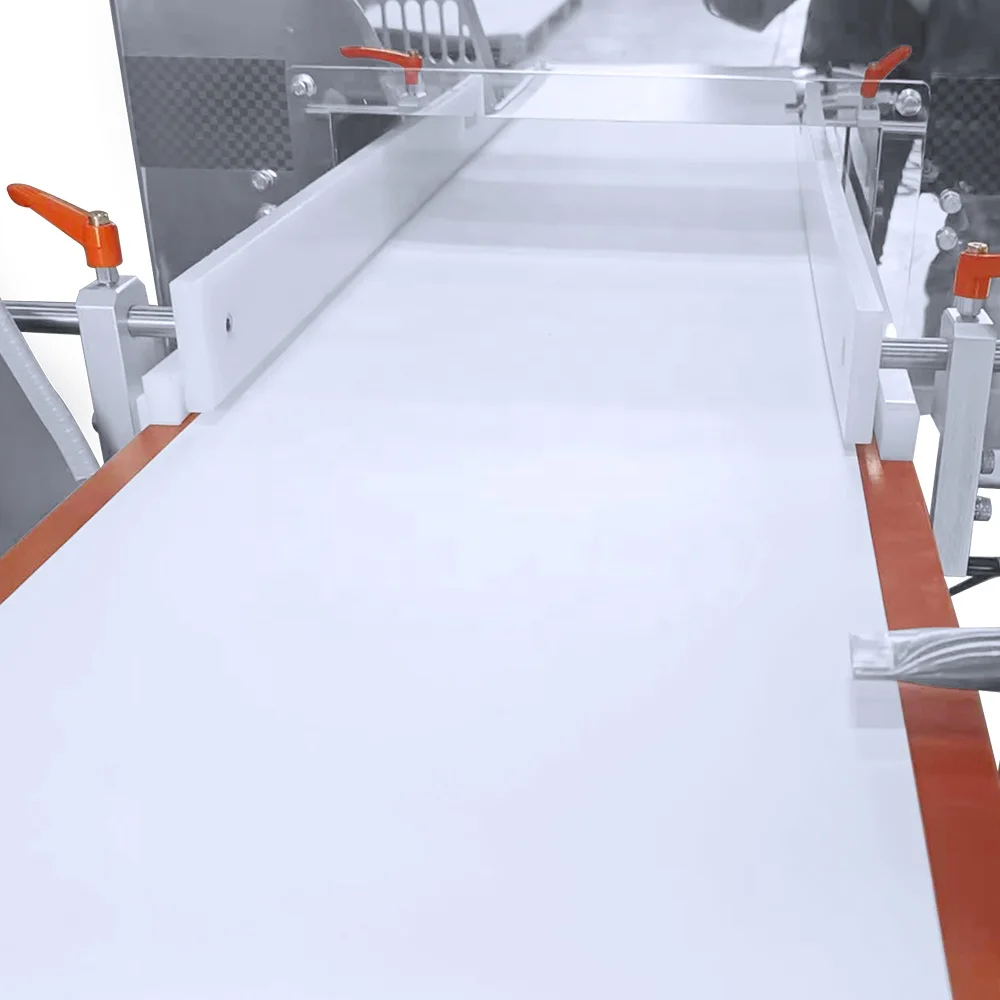

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.