In factories where things are made, measurement becomes critical, because everything needs to be just right. This is why a batch weigher is such a life saver! A batch weigher is basically a fancy scale that weighs a lot of stuff at the same time. Now, let's see how batch weighers help factories improve their processes

In mammoth factories that churn out everything from cheddar to Campbell’s soup, speed is critical. Using a batch weigher can accelerate this process by quickly and accurately measuring out ingredients for each batch. It ensures that workers are able to do other jobs while the batch weigher is measuring at the same time.

Quality control: ensuring products are every time made correctly To maintain quality control, batch weighers are critical as they help ensure that the correct quantities of feed are used for each batch. This prevents errors from occurring and to ensure that each product goes out of the factory up to standard.

A batch weigher means that life is so much easier for everyone in your factory. A batch weigher checks things quickly and accurately instead of measuring them by hand, which takes time and could end up wrong. This saves time, and makes everything run more smoothly.

If you need to have accurate weights for your pricing, a batch weigher will help your business run smoothly. It helps to make the product quality improved and production faster also saves time with low errors on the production end. Batch weighers are very useful for businesses and in long term, make your business cost effective and more efficient.

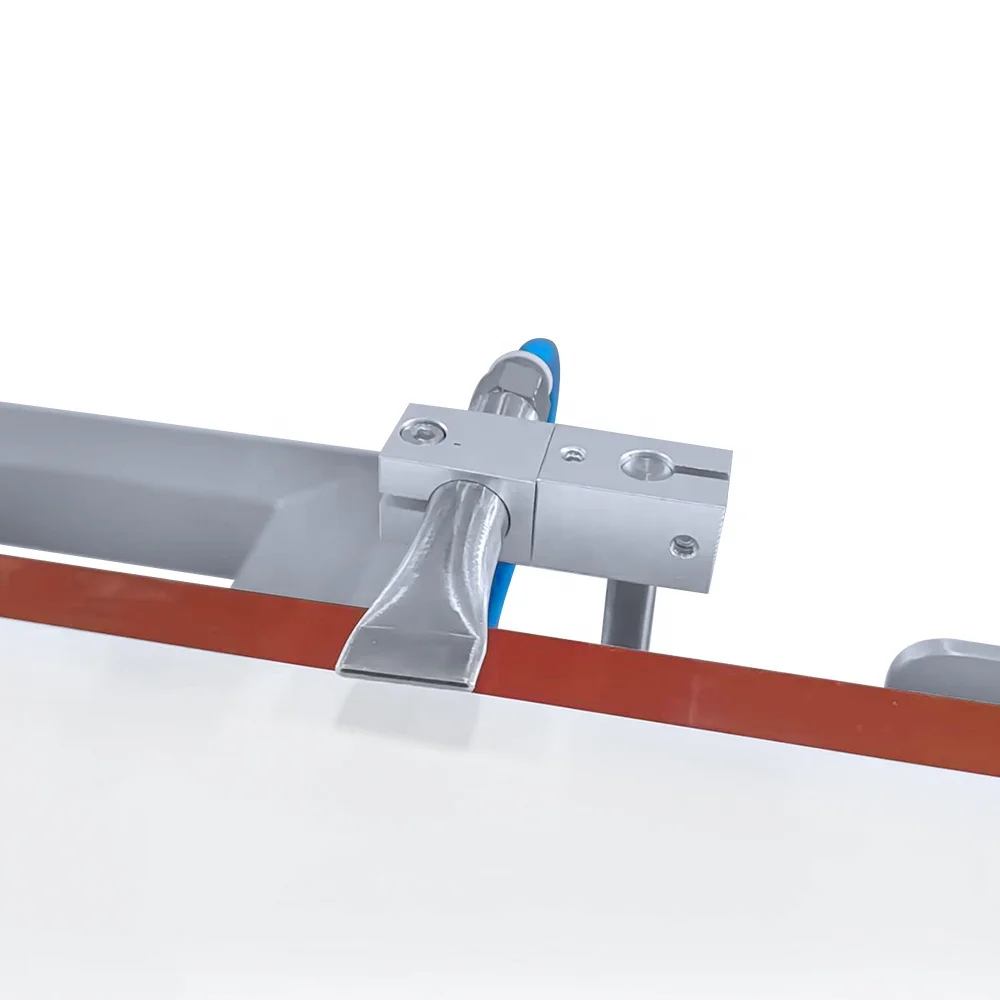

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.