X-rays are a special type of light that can pass through things and reveal what is inside. X-ray machines use these rays to see into objects, such as luggage at airports or mail-handling systems. But if you’re wondering how much these machines go for, there are a few things to consider.

Several factors affect the price of an X-ray machine. Cost can vary due to machine size, component quality, and the technology used. Machines with nice, upgraded features, such as clearer pictures or faster scanning, may cost more than simpler machines.

Jing Liang sells different X-ray machines at different prices. X100 is the most entry-level model and is suitable for small businesses or schools. You have a relatively simple interface and easy to use. The X500 is a bit more expensive but offers higher-quality pictures and a faster scan rate. For the X1000 model, it is more expensive -- but for businesses that need the wayherest technology.

For those looking to save, Jing Liang also offers second-hand X-ray machines at a bargain price. These machines have been used but refurbished to function as new. They provide the same quality as brand new machines, but without the price tag.

It's best to shop around for an X-ray machine to get the most competitive price. You should check their website or speak to a sales person for current deals, as Jing Liang often creates special offers or discounts. You might also consider purchasing a secondhand machine or leasing one to cut costs.

Price is always a consideration when purchasing an X-ray machine, but it not be the only factor you consider. You should also consider: How good is the machine? How much support can you expect from the company? How good a fit with your requirements is the machine? Investing a little more in a good quality machine will save you money in the long run through requiring less service, and general performance.

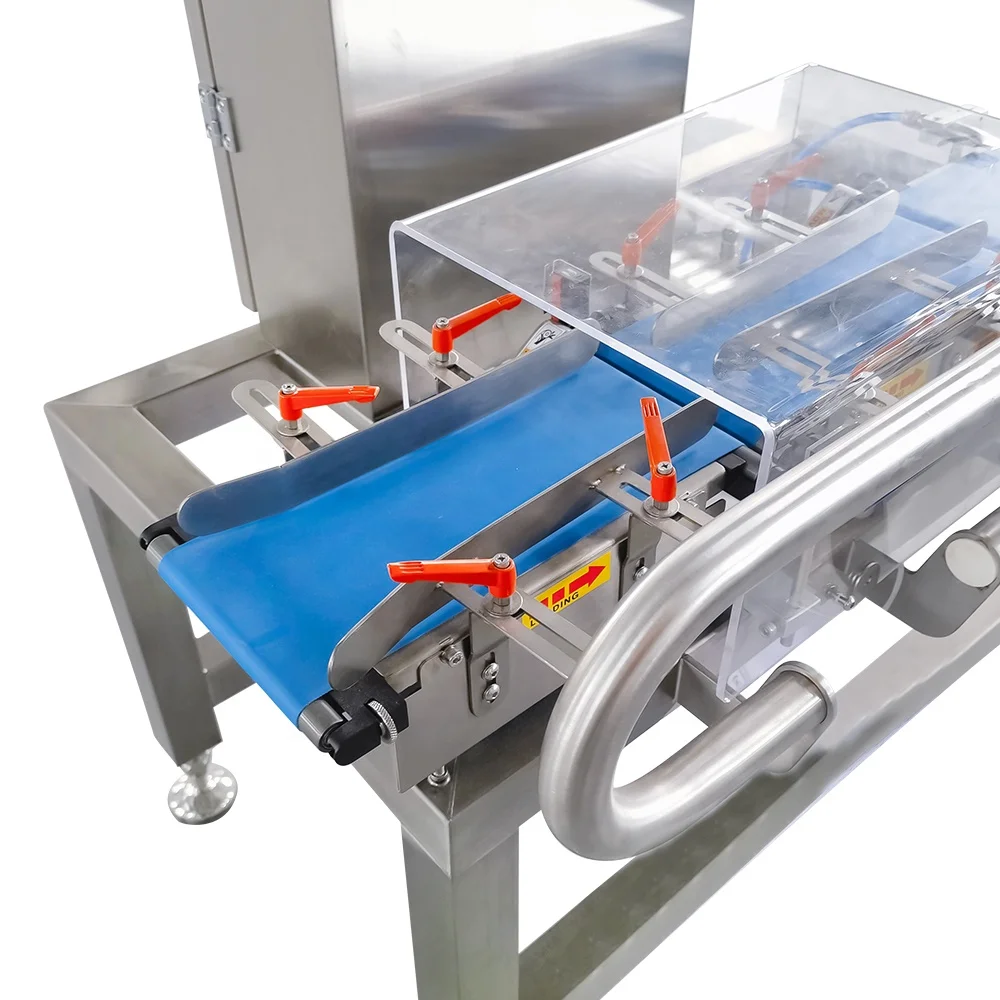

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services