Have you ever wondered how fruits and vegetables are separated into various sizes and grades before they arrive at the grocery store? A special machine known as a belted conveyor does just that. The food industry has several agricultural machines and one of them is a sorter that allows farmers to rapidly and easilygrade their produce.

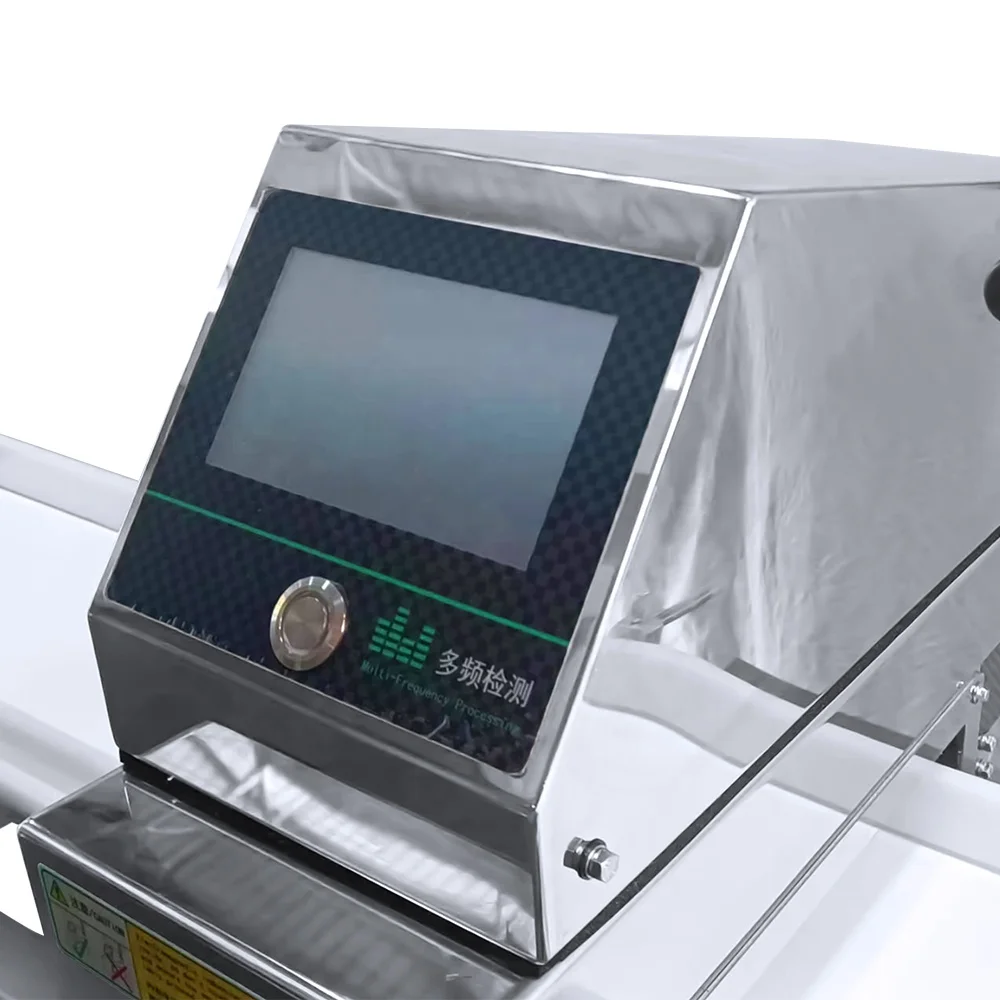

Grading machines work like a superhero for the farmers. They labor diligently to classify fruits and vegetables by size, shape and quality. Grading machines, with special sensors and technology, are capable of sorting hundreds of pieces of produce in a matter of minutes. Those allow farmers to save a considerable amount of time and do more critical tasks on the farm.

Farmers have several benefits by using a belt conveyor machine. Only the best quality produce gets to market after all, and it helps them save time. By classifying fruits and vegetables into different grades, farmers can receive higher prices for their premium produce. That means more money for them and happier customers at the grocery store.

They are also delivering a host of other benefits, such as speeding up the farming process. These machines allow farmers to work faster and produce more, allowing farmers to earn more money. Machines that grade produce also minimize food waste by ensuring that even slightly imperfect kinds are consumed rather than thrown away. This is a win-win for farmers and the environment.

Before grading machines came along, sorting fruit and vegetables was a slow, laborious exercise. Farmers had to do it all by hand, which took hours or even days. But with grading machines, sorting is now much quicker and easier. These amazing machines allow farmers to sort their produce quickly and accurately. For the last 4 years all they have done is improved the farming industry.

A super Japanese way of saying that, and this is a very important job of a grading machine, was to grade our food and make sure that it is of good quality. These grading machines separate quality produce into different grades, so we only get to eat the best and freshest fruits and vegetables. That is why when you buy an apple or carrot at the grocery store you can have the confidence that the product went through a grading machine and has been vetted and sorted properly and meets high quality standards.

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.