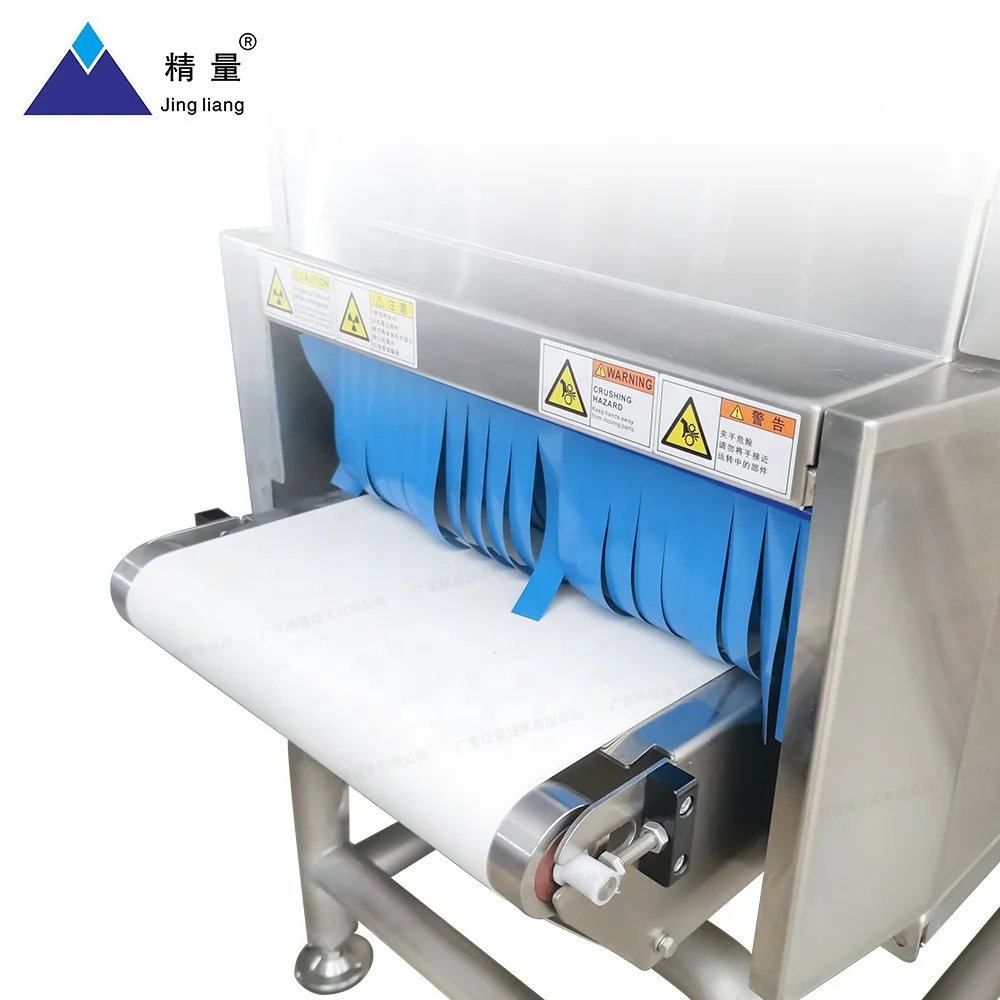

Companies can make their work better by learning about weighing conveyors. A weighing conveyor is an industrial machine that is designed to weigh goods as they are transported on a conveyor belt. This enables companies to use just the right quantity of materials, ultimately resulting in an improved product.

There are lots of good points of using a weighing conveyor. First, it’s time- and cost-saving by automatically weighing items. The machine can weigh several items at once, as opposed to workers weighing each item individually. It speeds up work and minimizes human error.

Weighing Conveyers Help In Making Products Better. Using the right amount of materials means companies waste less and create more uniform products. This makes customers even more satisfied and they return to buy more.

For accurate weight readings, a weighing conveyor Products needs to be serviced regularly. This also involves checking the sensors to ensure that they are functioning properly and repairing them if necessary. Companies also need to keep the machine clean, as dirt can impact the weight readings.

Hardly difficult to add weighting conveyor to production line. Companies have to determine where to place the conveyor and how it would work alongside other machinery. After a conveyor is installed, workers must be educated on how to correctly operate the device.

Lastly, companies must keep the maintenance of the check weigher conveyor by cleaning, checking the sensors, aligning the machine, and as per direction. These tips help companies ensure accurate weight readings on their weighing conveyor consistently.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.