When you need to weigh some things on a conveyor belt, you need a good and accurate tool. That’s the Great Belt Scale of Jing Liang. You can rely on our commitment to quality of our products to ensure that your requirements of weight measurement is going to be of the right angle.

Jing Liang’s Great Belt Scale uses high-tech tools to ensure you get the correct weight. The smart sensors and software in our systems deliver precise data you can trust, so you can verify the current weight of your materials on the conveyor belt with total confidence.

Selecting Jing Liang's Great Belt Scale makes your work speedier and better. Our system allows to monitor the weight of materials as they flow at every stage, enabling your decision-making to positively impact your yield and minimise waste. We have a simple setup which gives you access to the data and helps you analyze it to improve your work.

It is important to weigh things accurately because you want to produce more. Our system gives you very accurate measurements, thanks to Jing Liang's Great Belt Scale. [If you’re making bar graphs in Excel for your paper, you want to get the weights correct so they don’t just make you work better and produce more, albeit crookedly.]

Trust is a big deal when you need to weigh things. Great Belt Scale from the Great Belt family of scales by Jing Liang combines uncompromisingly strong performance with reliable accuracy. With measures you can trust, our system is designed for many types of businesses. Jing Liang Great Belt Scale — The Scale You Need to Rely On

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.

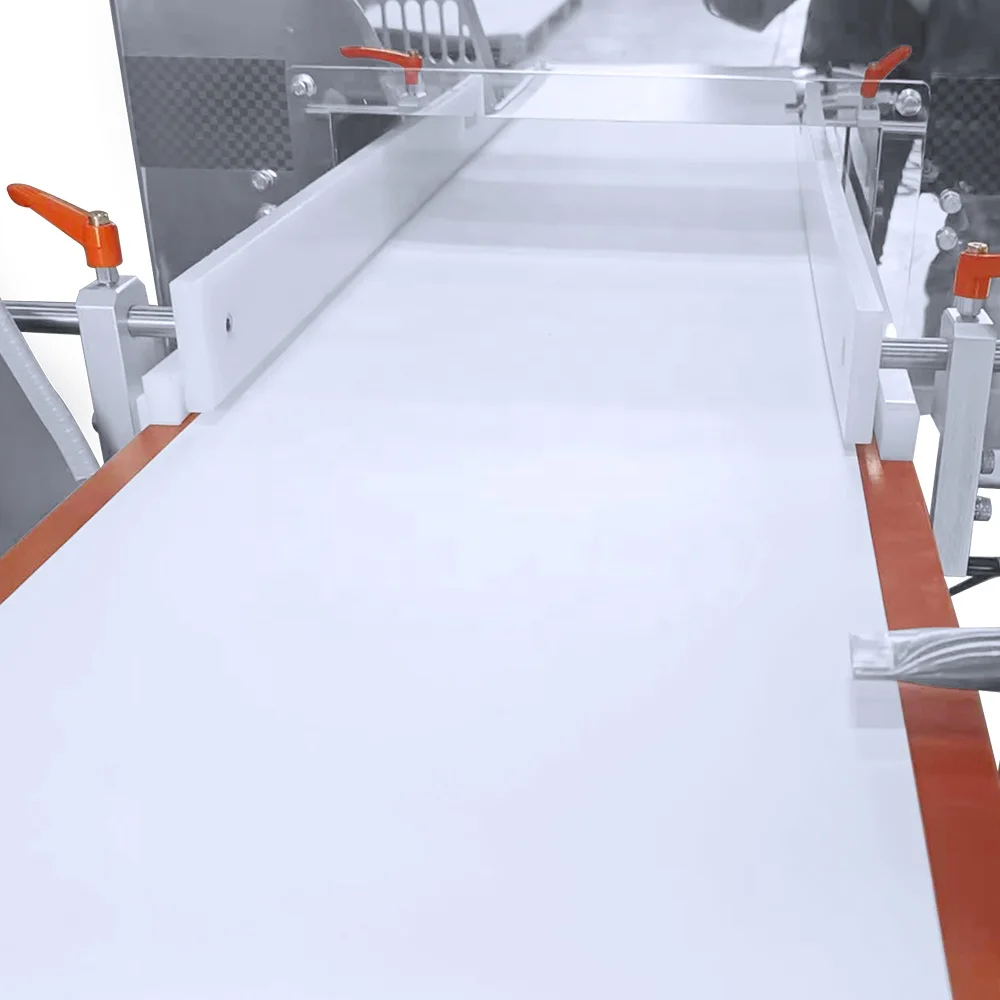

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.