Meat x-ray machines are indispensable machines for the food industry. They also help make the meat we eat safe for us. These Jing liang metal detector for meat processing have special technology that allows it to deep-dive inside into things like meat products and root out any foreign objects that ought not to be in there. How meat x-ray machines work and why USDA can’t do without them. Let's find out how meat x-ray machines work, and why the technology is so crucial when it comes to food safety.

Large carnivorous marsupials — meat x-ray machines have a lot to teach us about what makes food safe to eat. They can detect foreign objects, such as metal fragments, plastic pieces and even bones, in meat products. If the objects are not discovered before the meat is sold, they could pose a hazard to people who eat it.

Meat x-ray machines use a technology called x-ray imaging to see inside packages of meat. X-rays are a kind of radiation that can pass through things such as meat, but not heavier things such as bones or metal. They then scan the meat using x-rays to create images to determine if there are any foreign objects.

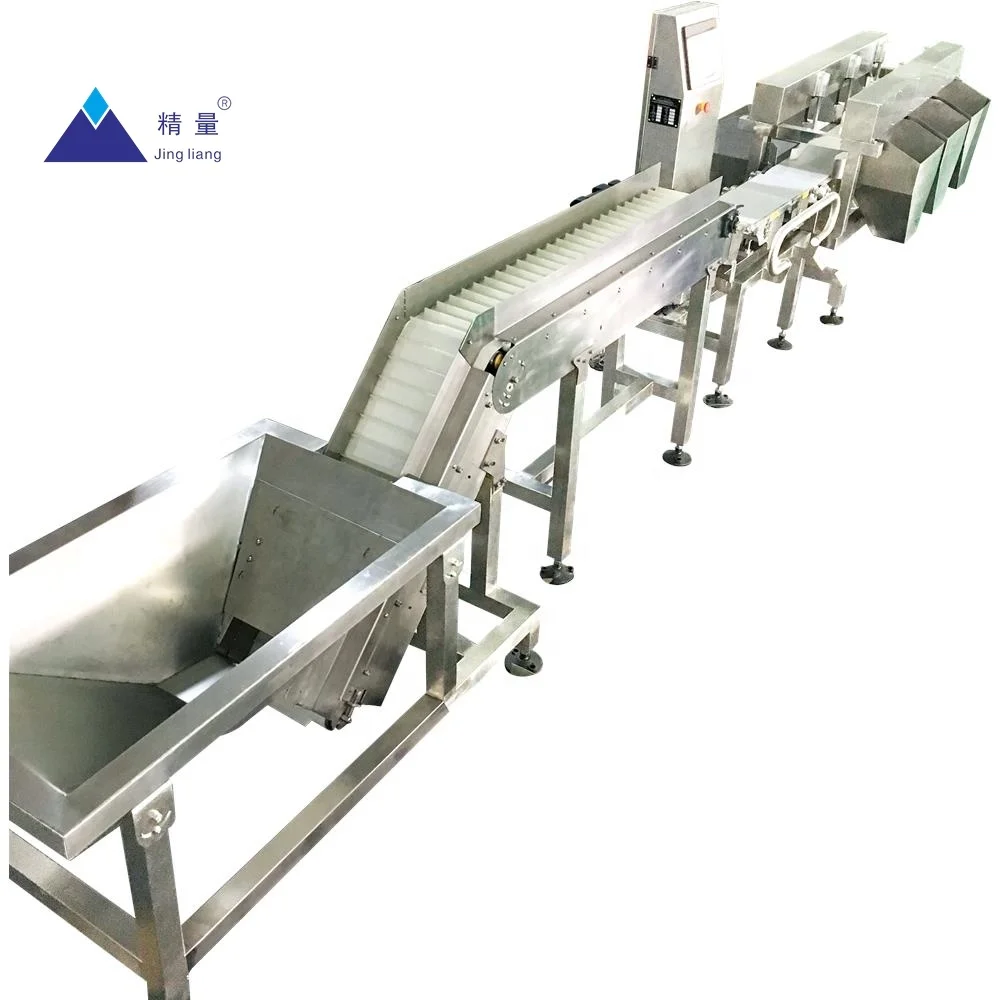

There are plenty of good reasons to employ meat x-ray systems in the food industry. One of the greatest effects is that they prevent bad meat products from getting to people. Jing liang X Ray Machine For Food help by detecting foreign objects early in the chain, ensuring only safe wholesome meat is put into the market.

Special computer programs read the images generated by the x-rays in meat x-ray machines. These programs search for particular shapes and weights, indicating the presence of things like metal or plastic. If the Jing liang x ray machine in food industry detects a foreign object, it alerts the worker, who then takes the bad meat off the line.

Meat x-ray machines make a difference in the food industry’s quality control. Jing liang x ray machine for food industry root out any foreign objects in the meat, near instantly and very accurately. This will help ensure that only safe, quality products are sold. It is also good for food companies, helping them maintain a reputation for quality and consumers’ trust.

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.