We compose till October 2023 You are on the verge of a surprise. They aid in keeping our food safe to consume. One such company is Jing Liang, manufacturers of these machines.

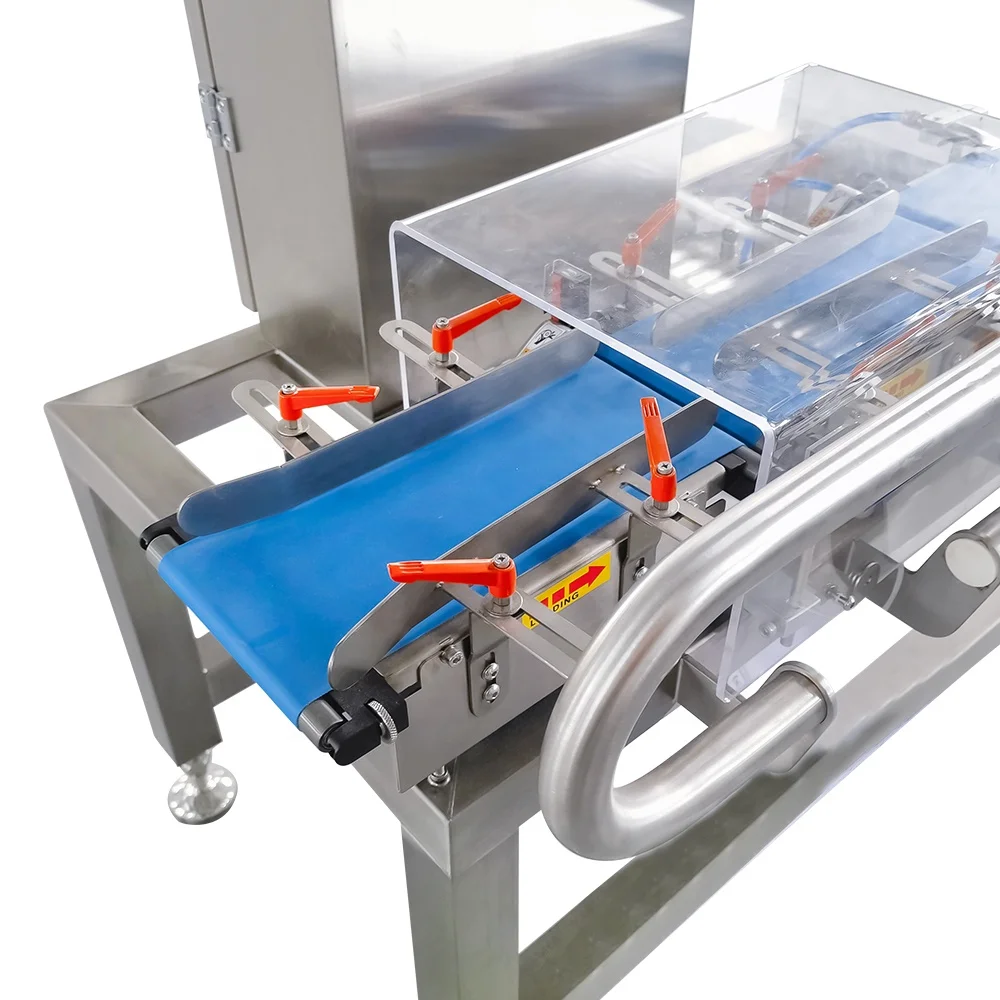

X-ray machines are kind of special cameras that can find out what is inside food. This allows food makers to ensure their products are safe. Jing Liang’s X-ray machines can detect metal, glass, bones and other foreign objects in food. And that allows them to get rid of anything that could be damaging to someone.

Food producers use X-ray machines to search for defects in their foods. When a machine detects something is wrong, like a shard of metal in a bag of potato chips, it signals workers to halt the production line. It ensures that hazardous food is not sold. Before it can feed an army, Jin Liang's X-ray machines very accurately check for hidden objects in food.

X-ray machines assist food producers in ensuring their products are properly made. They can also verify the size and shape of items, such as chicken nuggets, to ensure uniformity. This saves companies from missteps and lets them produce high-end food. X-ray machines from Jing Liang are fast and they help with making.

For any country, the task of food inspection is crucial to ensure that the food we consume is safe for human consumption. There, X-ray machines help a great deal. They can scan lots of things fast — something that would be too difficult for human beings. X-ray machines by Jing Liang are highly developed and they also help food inspectors to perform their job better and efficiently.

Food processors must follow strict requirements to ensure the safety of their products. To help them ensure that these rules are being followed, X-ray machines are used to look for any issues in the food. X-ray machines run by Jing Liang are state of the art and can see the smallest of issues. This provides food manufacturers with the peace of mind that their products are safe to be consumed by all.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.