Hence, Industrial X-ray Equipment plays an important role in ensuring the quality and integrity of materials. It allows us to peer into things without smashing them open. This is known as non-destructive testing, and is very valuable in many professions.Voicemails. Let's learn more about it!

Non-destructive testing allows individuals to check if a product is well-made without damaging the product. Special rays are used to see inside things and seek out any faults in the industrial x-ray equipment. This is crucial in industries like factories and construction sites where a minor error can lead to significant consequences. We can catch these errors during testing with Industrial X-ray equipment and remedy them before they become fatal.

In manufacturing, proper quality control is essential in order to ensure that the product is made to perfection. The Industrial X-ray equipment assists in verifying any defects or issues within the items. This ensures that the products are safe to use and meet criteria quality standards. Manufacturers with Industrial X-ray device get to deliver their products correctly and with better quality to customers and business, hence a win-win solution!

In recent years, Industrial X-ray equipment has made significant advancements. Join us here to read our article on Industrial X-ray machines. That allows us to look for even trace defects in products, ensuring that they are safe and of high quality. Due to these advancements, Industrial X-ray equipment has become a necessary tool for the manufacturing unit.

Quality control is very important to ensure that products are up to the mark. This is where industrial x-ray equipment comes into the picture as it enables manufacturers to inspect for faults / errors in the products. This type of equipment can help companies ensure that all their products are top quality and safe for the public. It plays a vital role in maintaining a positive image and making customers believe in them.

Industrial X-ray devices are employed in various industries such as aerospace, automotive, and electronics. That equipment improves efficiency and helps firms deliver faster and better service. That is because Industrial X-ray machines offer speedy inspections of products for defects, resulting in faster production with fewer errors. Therefore, Industrial X-ray equipment is a useful tool that improves the company's work and safety # # #.

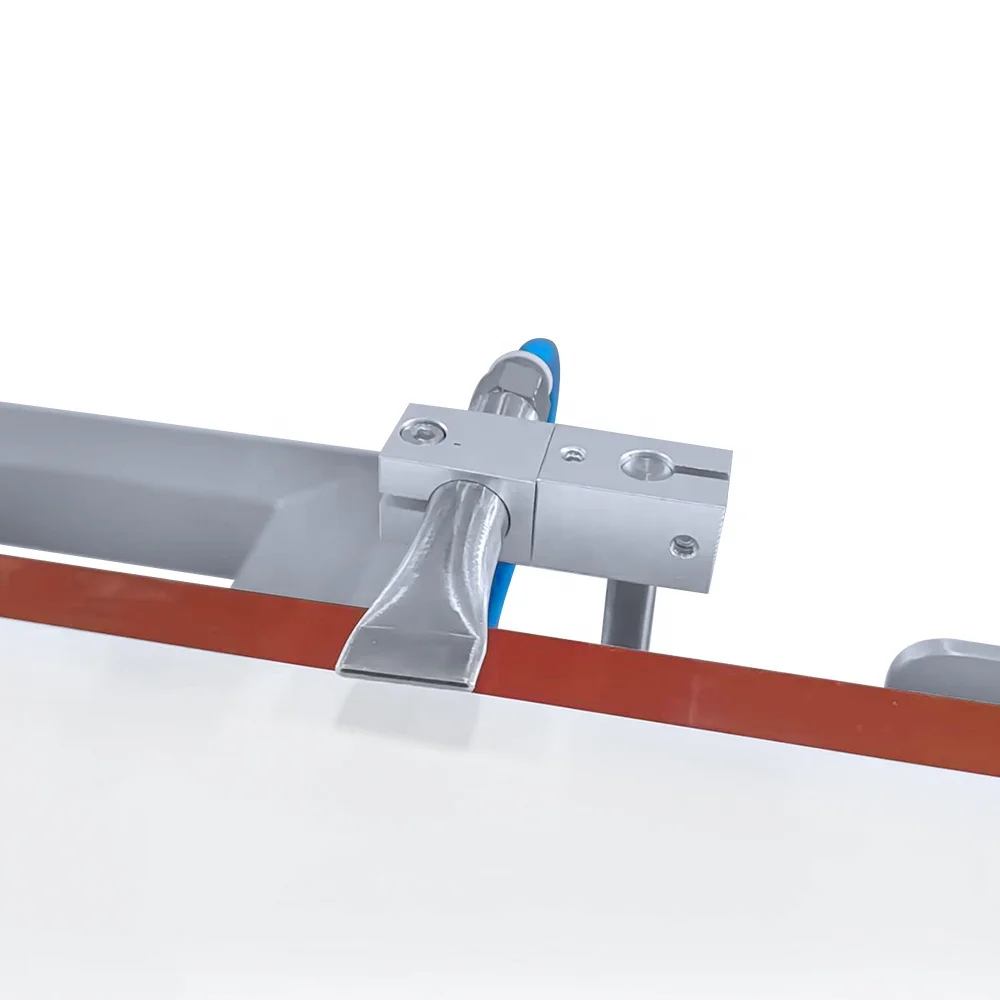

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.