Hello! Have you ever wondered how they measure heavy objects in factories and stores? This is where industrial checkweighers come into play! These industries use advanced software that assists with manufacturing usages of the right amount of materials to create the desired products. We will discover more about industrial weighing scales and why these are important when it comes to making things.

Precision really matters in manufacturing and it finds a way in. Picture a bakery that uses too much or not enough flour to make its bread, for example. The bread would not be good and customers would not like it. And that’s why industrial weighing scales are crucial. They weigh things precisely so that businesses use only exactly what they should need.

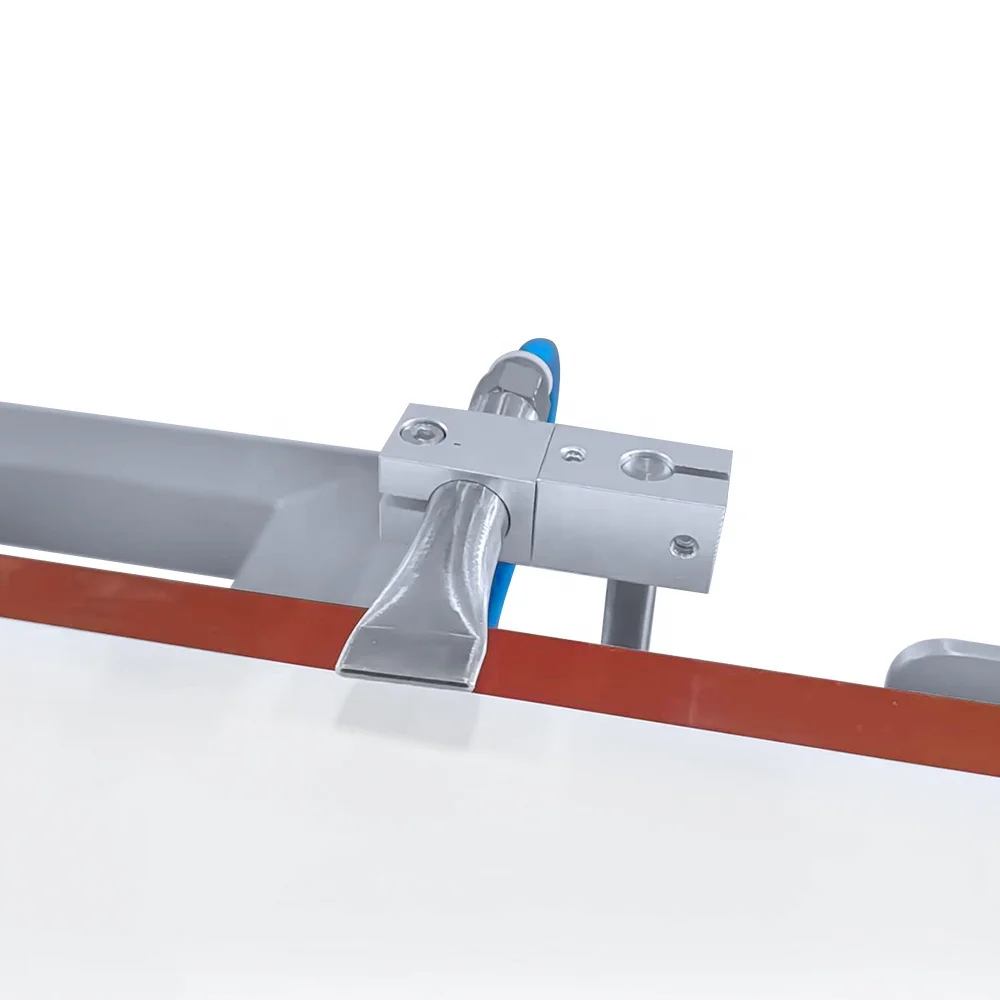

Making yourself efficient means doing things quickly and smoothly. The most types of belted conveyors make commercial works easier in terms of using the exact quantity of raw materials. Less waste and saving money in the long run. It is possible to produce faster with precise measurement, and customers will receive their orders on time.

Considerations when choosing an industrial weighing scale for your business You’ll need to determine what you’ll be weighing, how much weight you need to measure, and how frequently you’ll be using the scale. Different kinds of scales do different things, so it’s wise to select a model functionally suitable for your enterprise. Jing liang is a variety of industrial scales weighing to help you find the right one.

Technology is ever-changing and ever-improving, and industrial weighing scales are no exception. Today, these scales are better and more productive than in the past. So, some scales even sync up with computers and other devices for recording weight data. They help businesses to run at a faster and smarter pace with the latest industrial weighing scales.

The process of tuning an instrument in order for it to sound perfect is not so different from industrial weighing scales needing to be calibrated to remain accurate. Consider calibration as a kind of wellness visit; a form of adjustment that ensures the scale is reading weight accurately. Calibrations — we offer calibration services for our scales so businesses can be confident their measurements are accurate.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.