X-ray machines make things safe by allowing people to peer inside objects without opening them. The reason is to ensure well made products that won't hurt anyone. Jing liang has machines that perform this second important job. Why is X-ray testing equipment so useful?

In factories and other large-scale production and assembly environments, such as factories and large buildings where things are produced, it is crucial to perform proper verification. X-ray testing equipment acts like an X-ray machine for things and can look inside to see if everything that is there is working. This closes the loop before things fail or accidents occur. This is where Jing liang's X-ray testing equipment comes into play: they do a great job of keeping you running smoothly and safely.

You get to play with a toy you will only discover has a problem halfway through. That could make it hazardous to toy with. X-ray testing equipment helps ensure this doesn’t happen by looking inside toys (and other things) to see if there are any problems. X-ray machines from Jing liang are surprisingly good at checking that everything is safe and well made before it makes its way into stores for people to buy.

The technology is continually improving and evolving. This is true even for X-ray testing equipment! The imaging machines of Jing liang are special and advanced, using unique sensors and computers to observe the inside of objects more obviously. This helps catch little issues that aren’t so visible. This makes products made using Jing liang’s X-ray machines extremely safe and of high quality.

When an organization is going to procure the X-ray testing equipment, it need to consider certain key features. All the important features for desktop machines—you have fast scanning times, you have high quality images and controls which are easy to use. These features ensure that products are manufactured well and safe for human use. Zhao grew his company into one of China's biggest producers of industrial robots.

Non-destructive testing means checking objects without destroying them. X-ray testing equipment is extremely essential for this testing as it is used to check the insides of different objects without breaking them open. Jing liang's devices are widely used in nondestructive testing, reducing the maintenance cost for ensuring safety and soundness.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

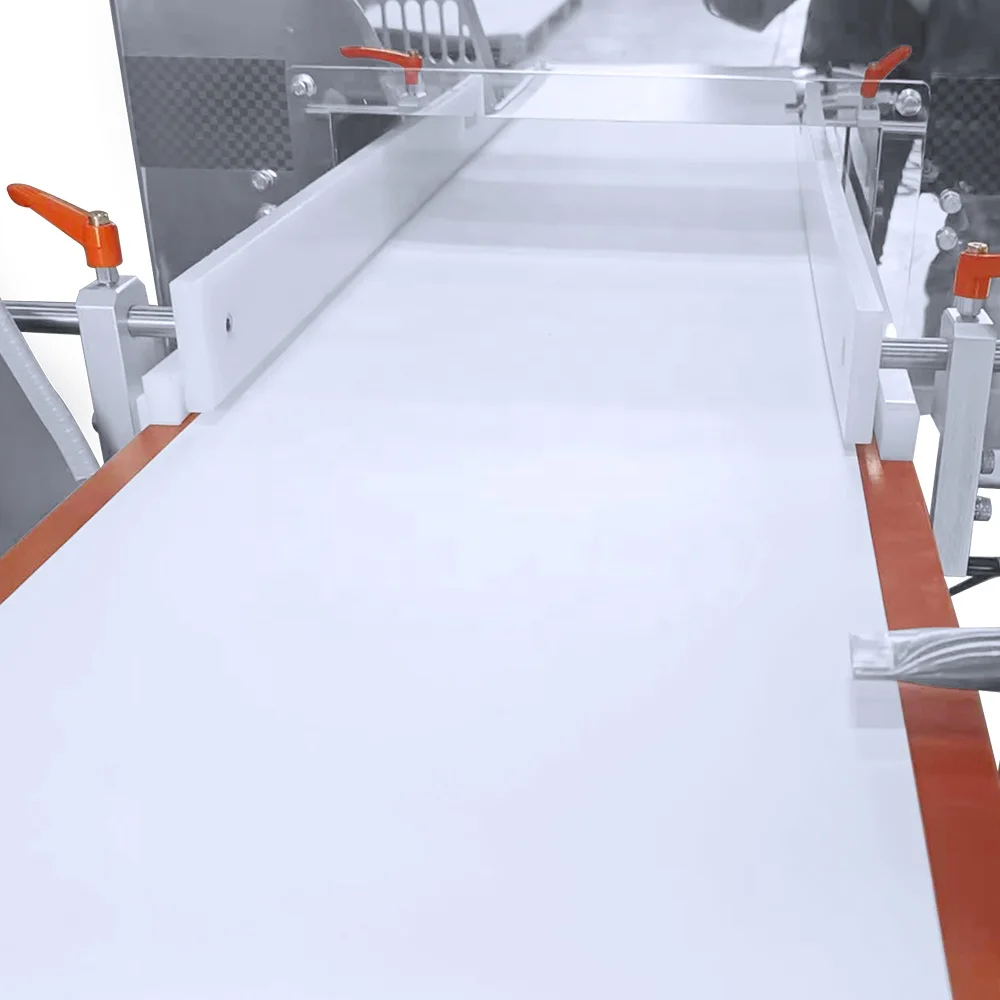

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.