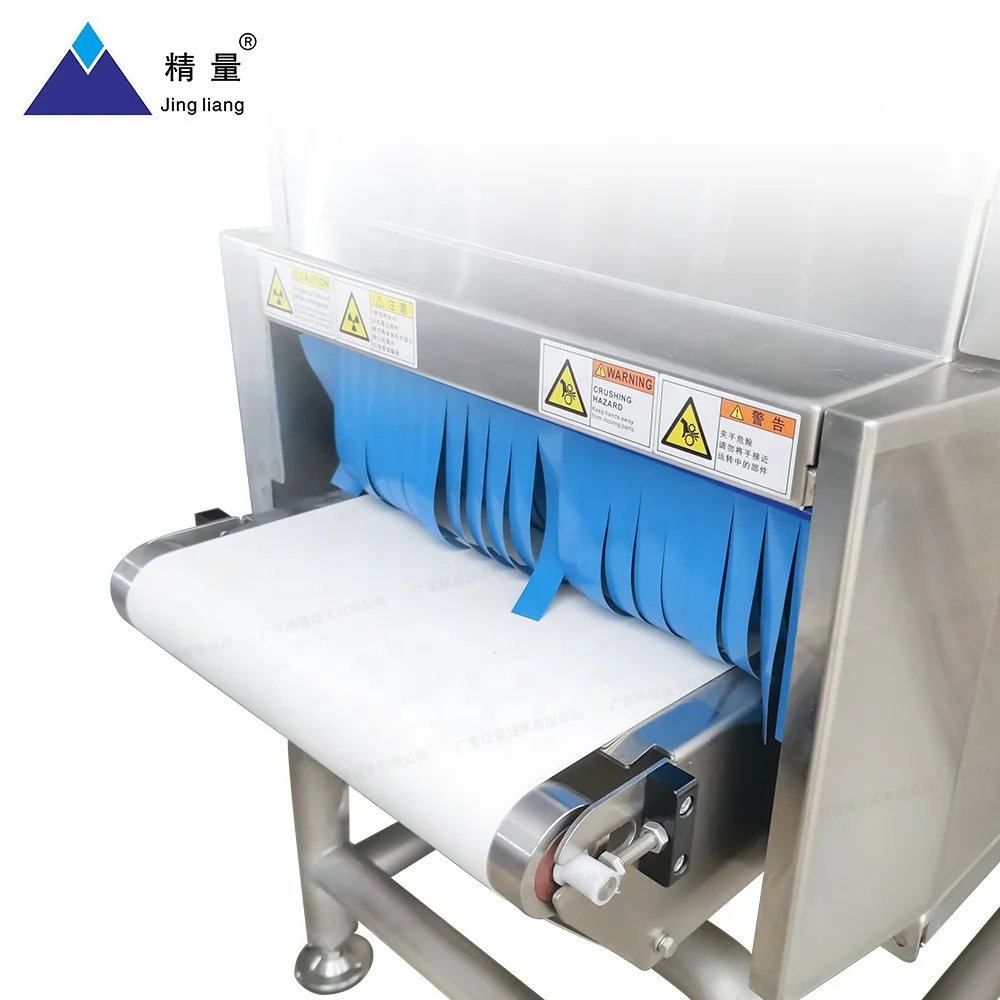

Metal detectors and Checkweighers are workhorses when it comes to a plant’s quality control program. They are intended to help ensure that products are safe and meet weights. But for these machines to work well, they have to be finely tuned. Calibration is when adjustments are made to ensure the machines are working properly and can detect any metal and accurately measure its weight. When they are out of sync it can be a problem. Goods may be dangerous to send, or businesses can lose money delivering the wrong weight. At Jing Liang, we know how important equipment uptime is, and offer some tips for calibration.

Steps to Properly Calibrate Your Metal Detector and Checkweigher

To ensure your metal detector Checkweigher combo are calibrated as they should be, there is some simple steps you'll want to take. First, read the manuals that come with your machines. You get some pretty important info from the user's guides about how to set them up correctly. It is a good idea to frequently calibrate your hydrometer. This involves checking daily or weekly, depending on your use of the facility. You can also schedule when to perform these checks. For instance, if you work out on the machines a lot during the week, let’s say check them first thing every Monday morning. Another good idea is to experiment on some tests pieces. These are special weights or balls of metal where you know exactly how much they weigh. By passing these through the machines you can verify they detect properly. If the vending machines can’t register the metal, or don’t weigh properly, something is broken and must be fixed. Finally, maintain a log or some form of record of all your cal checks. Jotting down what you find can help you identify patterns or recognized issues over time. This gives you a chance to spot problems before they become major issues.

Choosing a Reliable Calibration Service for Your Equipment

You are going to want a great company for calibrating your Checkweigher and metal detector. You don’t want to hire a service only to find out that they will not be reliable or the sort of business you will ask them, “When can you guys start”? Begin by requesting recommendations from fellow companies in your area. They can also tell you about their experiences and refer you to a service that they trust. It can also be helpful to read online reviews. You can also get a sense of which services are good in the comments customers leave. When you speak with a calibration service, inquire about their credentials. They should have trained personnel who know how to operate these machines. Don’t forget to inquire about their process. A good service will explain how they check and calibrate the machines. We also provide calibration at Jing Liang. We have access to parts suppliers for all makes and models that include everything from pressure washing equipment brands to hard-to-find potato handling equipment. By keeping your machines calibrated, you can enjoy the peace of mind that comes with knowing your products are safe and compliant.

The Importance of Proper Calibration Equipment for Metal Detector Checkweighers

For metal detectors Checkweighers it is very importance for you to have the correct calibration equipment. It's so this stuff works properly and gives accurate readings to these machines. When in need of calibration instruments you can trust, first turn to great quality. Look to suppliers that cater to the food processing and packaging markets:readers can tell us who some of those great companies are. Those suppliers usually have high-quality tools that you can rely on. It’s also a good idea to do some online research for reviews and ratings of various calibrations tools. You may find industrial equipment-focused websites useful. There are often comments from other users, which can help steer your decision.

You should also network with industry experts. You know someone who works with Checkweigher metal detector, ask them where they buy their calibration gear. They can exchange tips and may direct you to tools that they think are good. Be sure to use quality equipment so you can be confident that your machines are calibrated properly. At Jing Liang, we want to offer you the top equipment and support so that you can keep your metal detector Checkweighers in service.

If you're looking to streamline your calibration process, here are some other steps you can follow. First, identify and follow a consistent calibration schedule. This will enable you to catch any problems before they manifest into large ones. Repeat every month or a quarter, depending on how often use the machines. Next, educate your staff about calibration. Things will go faster and easier for everyone when they know what to do. Also, perhaps develop a “calibration checklist” so that the staff actually follow it. This may serve as a good way for them to remember all of the steps and make sure nothing is left out.

Using Technology to Streamline Calibration for Metal Detector Checkweighers

To maximize your calibration task, a great thing to consider is the use of technology. With a lot of the newer metal detector Checkweighers, they have software that will help with tracking calibration records and a variety of performance. This can save you time and help you to identify trends. At Jing Liang, we recognize the value of using high-tech solutions to ensure productivity. And, of course, never stop looking for new calibration methods. The landscape is always changing, and keeping an ear to the ground can help you discover new or better ways to calibrate your machines.

Last but not least, a breakdown of the newest advances that are taking metal detector technology by storm. Artificial intelligence (AI) is the biggest trend. AI has the potential to help machines learn from historical data and use real-time information to make improved decisions. That means that meat metal detector and Checkweighers can be designed to be smarter and have more accurate algorithms. Another. trend is on hygiene and safety.

Furthermore, wireless is generating increased interest. Wireless, machines can directly send data to computers without wires. This might help give the whole thing structure and organization. At Jing Liang, we are also crystal enthusiasts not only do our hearts beat for these new developments; but we search and find ways to utilize them in our own products. Keeping abreast of these developments will enable you to ensure that your calibration processes are accurate and up-to-date with current technology, providing you with more efficient and effective operations.