Give me your article about the importance and purpose of a checkweigher metal detector in food factories. It helps ensure food products are the proper weight and they are free from metal debris. Why are checkweigher metal detectors important and how do they work in a food factory?

You want to ensure that each bar weighs the same amount so that everyone gets their fair amount of chocolate. If one bar is a little too light, it might not have enough chocolate in it, and if it’s a little too heavy, people might not get what they’ve paying for.” A Jing liang check weight conveyor ensures every chocolate bar is just right.

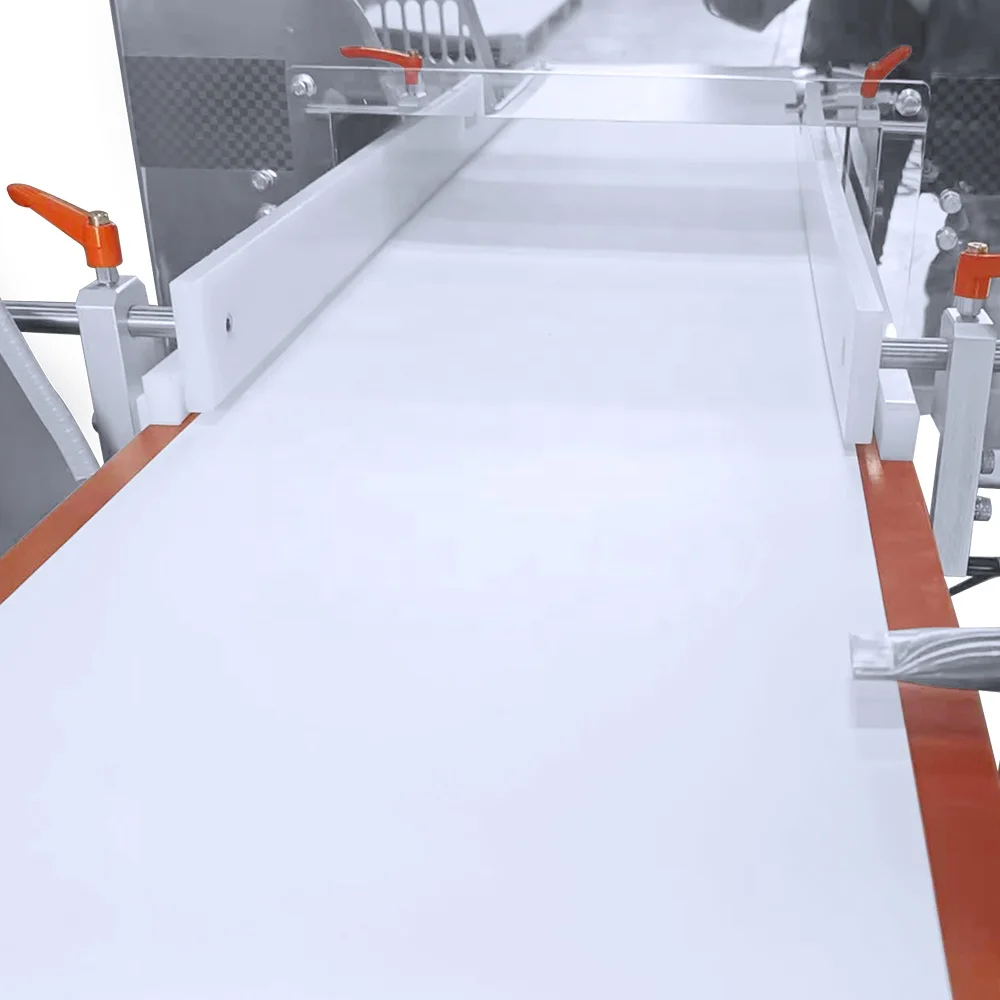

When producing a large volume of food products, everything must run smoothly and efficiently. It weighs the goods quickly and scans for metal materials in one swoop. This saves time and ensures that all the products are edible.

Quality control or QA means verifying that the food products are safe for consumption. A weight check conveyor is instrumental, as it checks for any little pieces of metal that may be dangerous if consumed. It also ensures that individual products are the right weight, and customers get what they paid for.

In the end, a Jing liang check weigher in food factory would save money. If a product is the wrong weight or contains metal, catching these issues early will prevent an entire batch ending up in the bin. And that means less money lost and happier customers.

There is some factors to consider in selecting Jing liang check weigher machine for food manufacturing factory. You want to ensure that it can weigh the products accurately and also check well for metals. Another thing to think about is the size of the products and how quickly they need to be checked. Ensure everything flows smoothly in the food factory Utilization of key check weigher metal detector

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.