Ans: As you might have seen those X-ray inspection machine, they are very cool because they can look inside the baggage as if it is magic! They use specialized technology to assist with making sure things are manufactured accurately and function as they should. So, let us see what makes x-ray inspection machines work and why they are needed for various jobs.

X-ray inspection machines shoot x-rays beams to photograph the contents of objects. These machines use sensors to see how x-rays penetrate different materials. The sensors create images that reveal if there are any issues within an object. Think of it as a special camera that allows you to see inside everything to make sure its all good!

x 、 And food industry machines, for example, x-ray inspection machines check for the presence of contaminants, e.g. metal or glass in food. This prevents people from consuming something harmful. X-ray inspection machines used in the manufacturing industry can detect flaws in products from cars to electronics before the products are sold. This ensures that companies can follow to be certain that their items are solid in nature and won't break without any problem.

X-ray inspection machines are fast and accurate so they have transformed quality control by finding defects in their products. So before these machines were invented, they would have to settle for looking at things or testing them, neither of which was as effective. X-ray inspection machines let companies spot potential issues inside products without having to tear them open. Not only does this cut costs and time spent on a product, it helps in making sure a higher quality product is delivered at the end of the development cycle.

X-ray inspection machines are powerful tools that can identify even small defects in products. These machines can look for things like cracks or dents or air bubbles that we simply can’t see. X-Ray inspection machines help companies discover these issues early and also rectify them before the item is shipped. Helps avoid recalls or returns, saving money for companies and maintaining their reputation.

What they use to achieve these weighted things are advanced technology machines that show quite clear images of those objects. These machines are able to produce detailed images that provide a good view of the interior of products. This allows companies to uncover any issues as well as defects promptly and accurately. With the clear images provided by x-ray inspection machines, companies can ensure that their products are of the highest quality and safety standards.

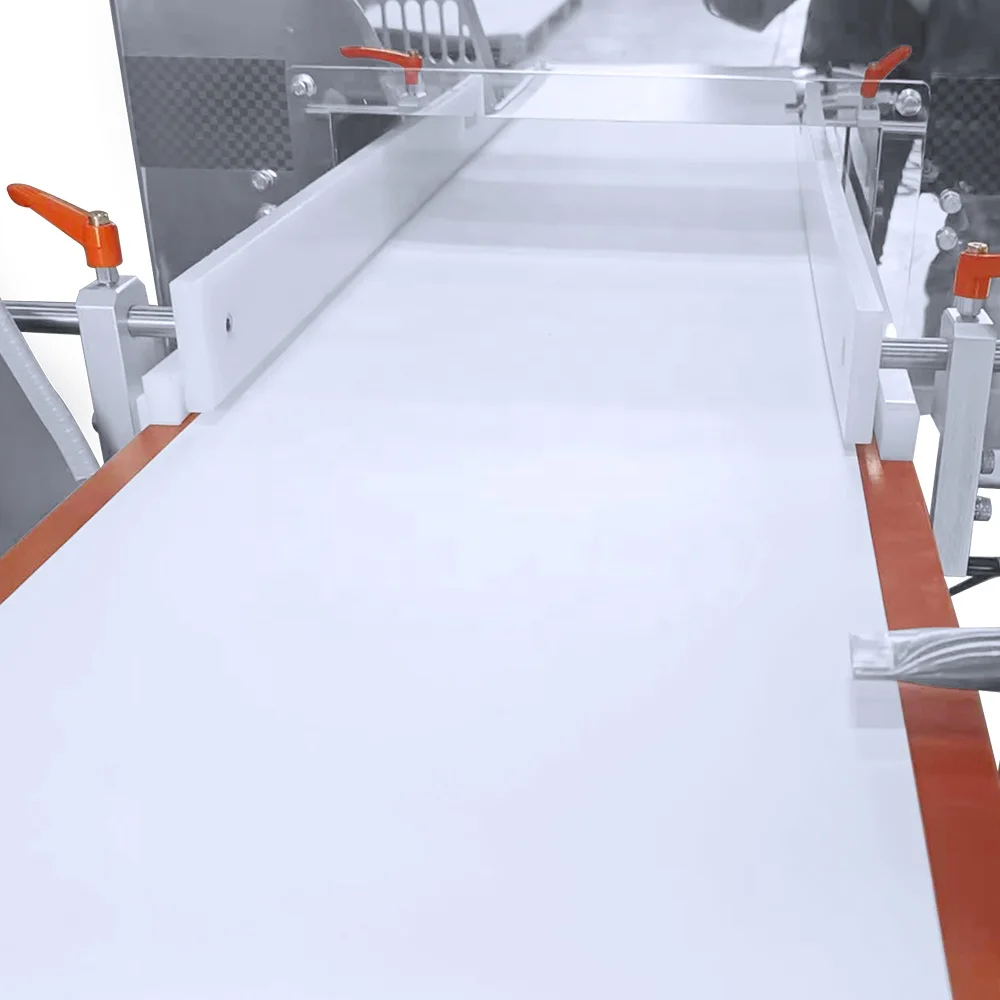

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.