Hey there! Ever thought about how things move around in a large factory? Enter the weigh belt conveyor! A weigh belt conveyor is a type of machine that ensures the correct transfer of materials. So, let us understand what a weigh belt conveyor is and why it is so great.

For starters, the weigh belt conveyor allows for easier material handling. A weigh belt conveyor measures exactly how much is being moved, rather than estimating it. This minimizes the time and effort you previously used, thus ensuring everything is sent to the right destination without mistakes.

Moving on, these devices assist workers in the better handling of materials in a factory or warehouse. They ensure that each item moves at the right speed and in the right volume. This helps to avoid spills or accidents and has everything flowing smoothly.

With a weigh belt conveyor weight Products control very important. If workers make sure each item is below the right weight, you can avoid a situation where something is too heavy or too light. It protects, and ensures that the process is successful.

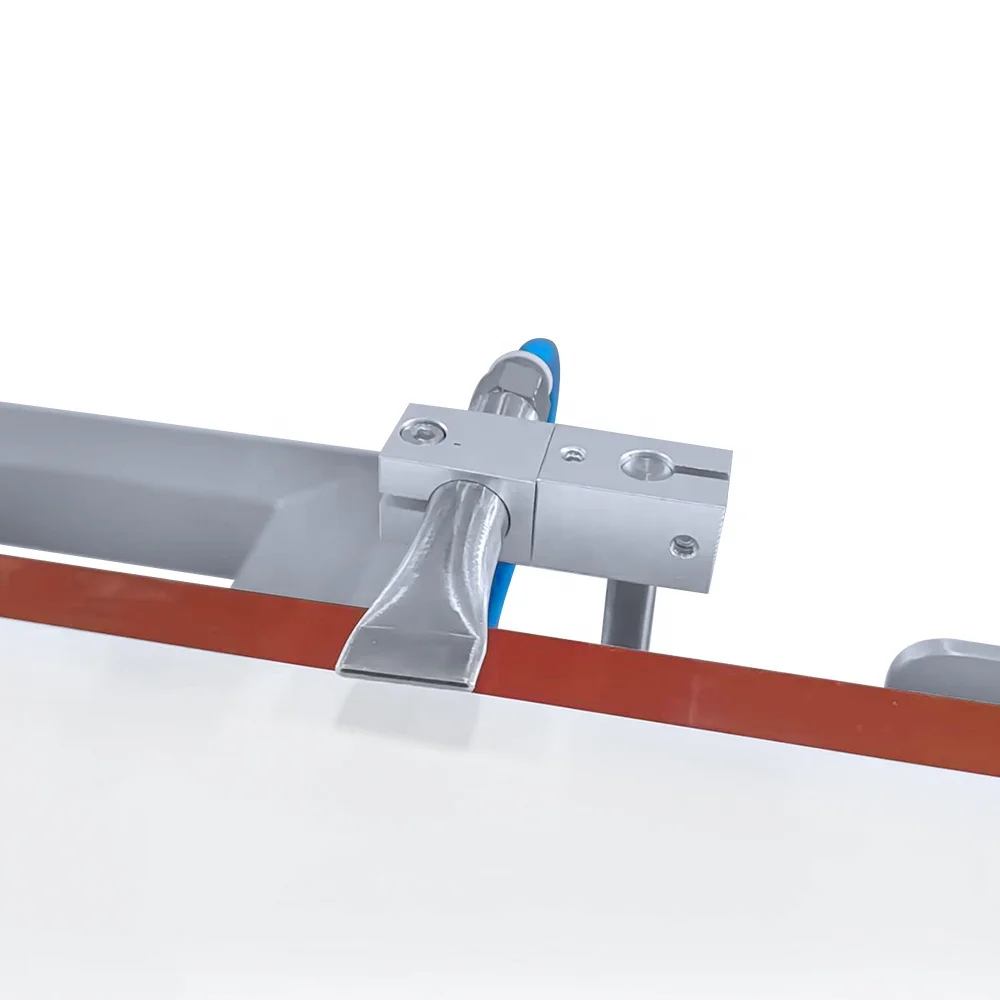

The awesome thing about weigh belt conveyors is they ensure the accuracy of measurements. Weigh belt conveyors using special sensors and technology ensure that everything is moved precisely. This will prevent mistakes and ensure everything runs smoothly.

Finally, weigh belt conveyors can be adapted for specific requirements. A weigh belt conveyor can also be adjusted to ensure that it can handle everything perfectly if you need to move big items or small items from one place to another. It allows work to be done more efficiently and keeps everything running smoothly.

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.