Well, metal detectors play so much vital role in maintaining the food from safe and edible. Jing Liang () is a food-detection metal detector manufacturer. Join us in exploring how these metal detectors work and why they’re important.

Metal detectors are special detectives that find little bits of metal in foods. They help out in factories that make food, to ensure that no bits of metal end up being added to what we eat. If metal enters our food, it infection is very dangerous. Metal detectors like the ones used by Jing Liang are always keeping our food safe.

Quality control means doing everything we can to ensure our food is the best it can be. Metal detectors assist by rapidly locating metal fragments where food may have been finished. Metal detectors made by the company Jing Liang are excellent at detecting even tiny bits of metal. This ensures that our food is safe and tasty.

Streamlining is doing things better and quicker. Metal detectors also speed up food production by quickly scanning each batch of food for metal fragments. That saves companies time and money. Without the use, Qingliang's metal detectors are a lot easier to use and the detectors can help check food very quickly to improve the production process.

These are undesired objects which are atypical to our diet, such as metal shards. Metal detectors are used across food supply chains, quickly locating bits of metal to keep our food safe. Metal detectors: Jing Liang (our food manufacturer) is very reliable and make sure that the food is free from any unwanted objects. That ensures that our food is safe to eat.”

Food safety rules are regulations implemented by food companies to ensure that food is being consumed as safely as possible. Metal detectors are crucial for the food industry, which ensures that no metal particles got into the food. The metal detectors built by Jing Liang are designed to comply with stringent food safety regulations, allowing companies to protect the public.

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

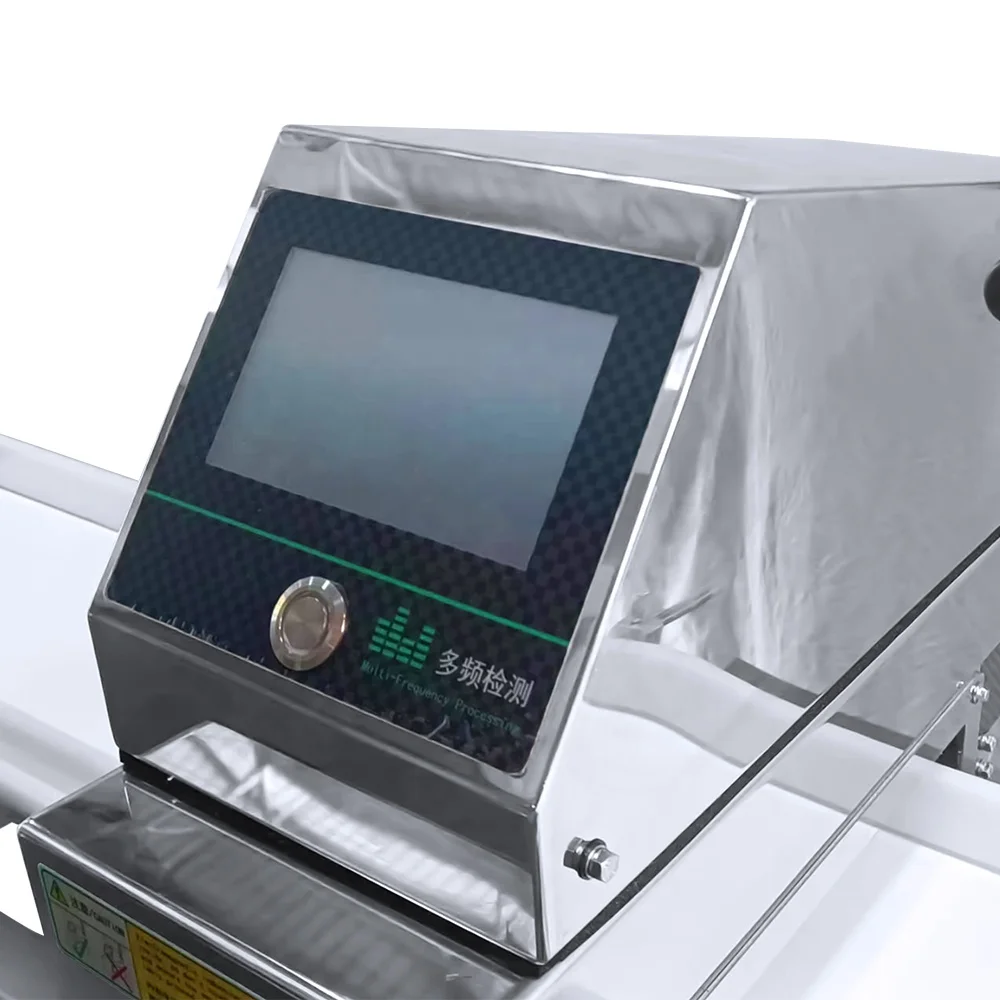

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services