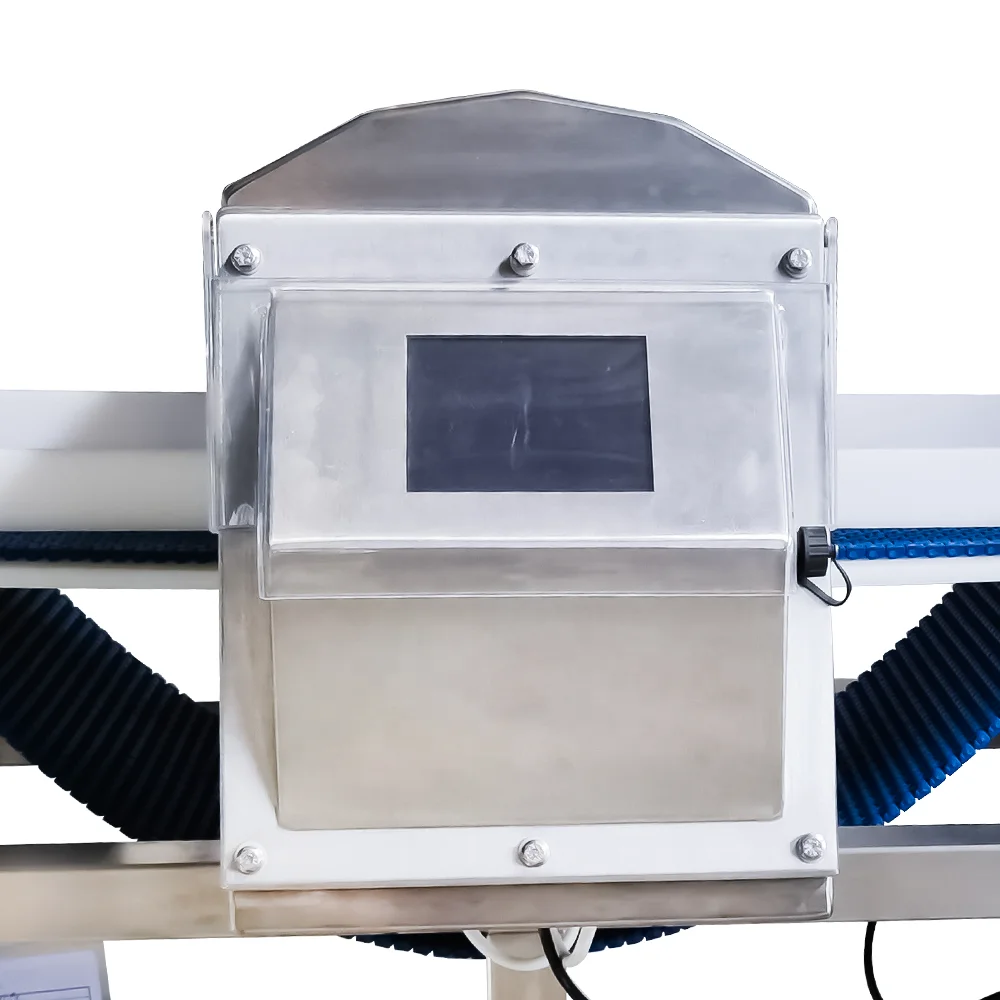

Metal detectors are special machines that make sure our food is safe to eat. They are key players in the agri-food supply chain. Jing the Liang company uses metal detectors to ensure food is good and safe.

Metal detectors can detect small metal fragments in food during the manufacturing process. This is crucial because even bits of metal can pose a danger if someone ingests them. The machines emit signals that bounce off whatever metal is in the food and notify workers if any metal is detectable. It can help food manufacturers locate and eliminate any metal before the food is packed up and distributed to grocery stores.

Metal detectors help ensure food is safe by screening for metal fragments that can cause damage to a person. If metal is discovered during the food production process, workers can halt production to inspect the food for safety. This avoids accidents and ensures that everyone eats safely.

Food manufacturers take advantage of metal detectors as they prevent the contamination of metal into food products which is very crucial. In the absence of these detectors, there is a risk of metal entering food, which can be fatal. Companies like Jing Liang use metal detectors to help ensure their food is safe for people to eat.

Metal Detectors in Food Processing are good in many ways. One positive note: they help ensure the food is safe. That is trust building for customers, as they know they are receiving good quality food. Another benefit is that metal detectors can prevent companies from big trouble, such as having to recall food later, by detecting metal earlier in the process.

Metal detectors enable food companies to comply with key regulations for ensuring food safety. There are strict guidelines to ensure that what we eat is safe. Metal detectors allow businesses to prove they are complying with these regulations and providing customers safe food.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.