A conveyor for food industry is a specialized machine that helps food manufacturers ensure their products are the correct weight. This is extremely relevant for food entrepreneurs as it allows them to monitor their production process. By using a food checkweigher, they can ensure that every package contains the correct amount of food. This is crucial so that customers always receive the same amount of food.

Example of large equipment and instrument such an food checkweigher.children's kitchenware.skills menu. This is known as portion control, which ensures that the correct amount of food is included in each package. By implementing a checkweigher to test food throughout the production process, companies can trust that their food packages are a proper fit. This assures customers that they are receiving the same amount of food with each package.

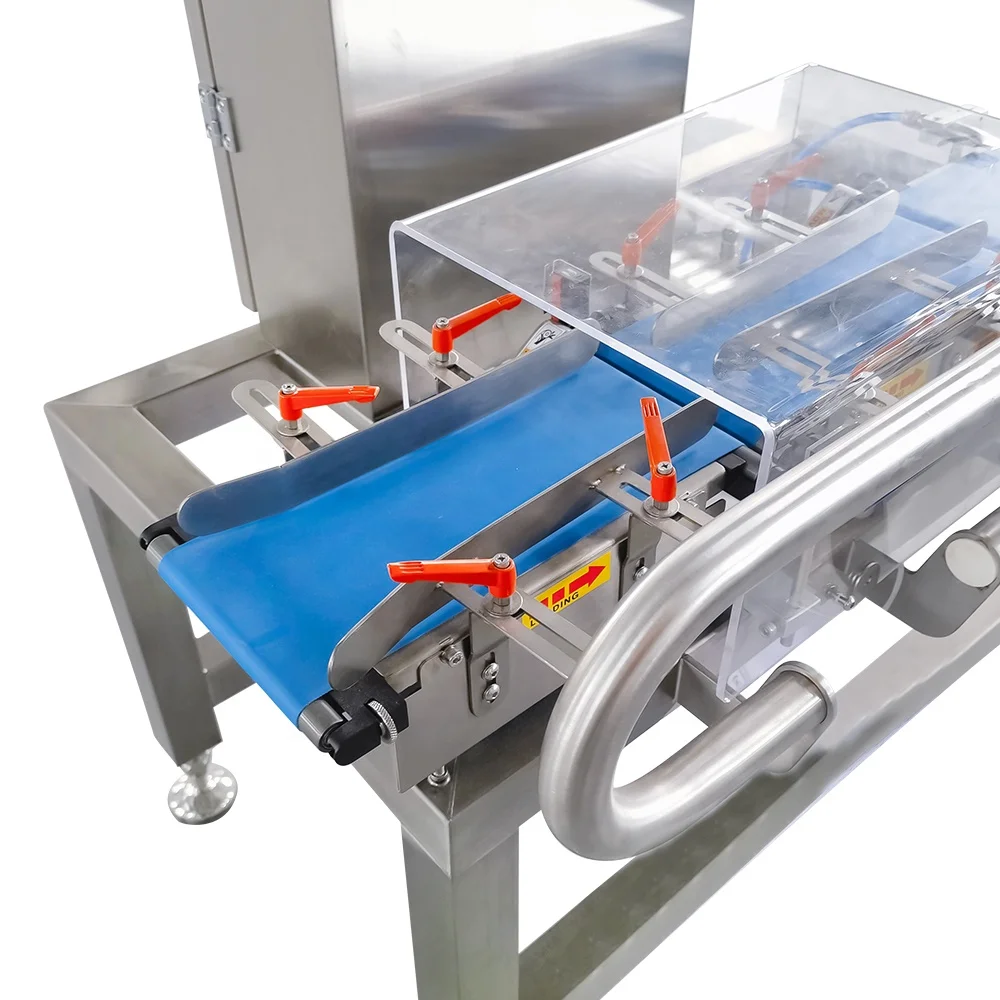

This can be a belted conveyor for food production companies. That way they can ensure they are not overcooking. They can time and money because they only make what they need It also helps them ensure they have enough to feed customers.

For food companies, compliance with product weight regulations is paramount. Incorrect food size can lead to issues. A food checkweigher can help ensure compliance with weight regulations. With the help of a food checkweigher, companies can be confident that their products are the correct weight every time. It helps them adhere to necessary regulations.

Food companies have to be careful to not over produce because any leftovers lead to food wastage. And that is a bad thing for the company and for the environment.” Food checkweighers enable companies to produce correct amounts of food every time. In this manner, they can decrease waste and optimize resources. It saves them both time and money by not wasting food.

A food checkweigher has an important function or role to play when it comes to food companies, as it ensures that their products are always of the correct size. This allows customers to receive the same amount of food in each package. Therefore, a food checkweigher ensures that the company is providing customers with reliable food products. However, this builds a sense of trust, and therefore the customer is more likely to return to purchase further.

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.