Not to be confused with a regular ldquo;scale,rdquo; automatic conveyor belts are specialized scales that are designed to weigh products on a conveyor belt. This allows companies to track their earnings and movement. Time to know more about conveyor belt weighers!

Sensors mounted on conveyor belt weighers are essentially used for measuring the weight of items as they go over the conveyor belt. These send signals to a computer, determining the total weight of the items. This directly allows companies to monitor their manufacturing processes and ensure that everything is running smoothly.

With x ray conveyor belts, businesses can instantly visualize their earnings. This can assist them in adjusting their production process to function better. If the weigher indicates that are making too much of one product, for example, they can adjust things to ensure they make more of something else. This can help companies save both time and money.

Advantages of using Conveyor Belt Weighers There are numerous advantages of having conveyor belt weighers. They assist businesses in ensuring that they are only producing what they require, helping to minimize waste. They also monitor how much companies are making to ensure that they meet their production targets. Additionally, conveyor belt weighers can identify the problems in the manufacturing process to allow for a quick fix.

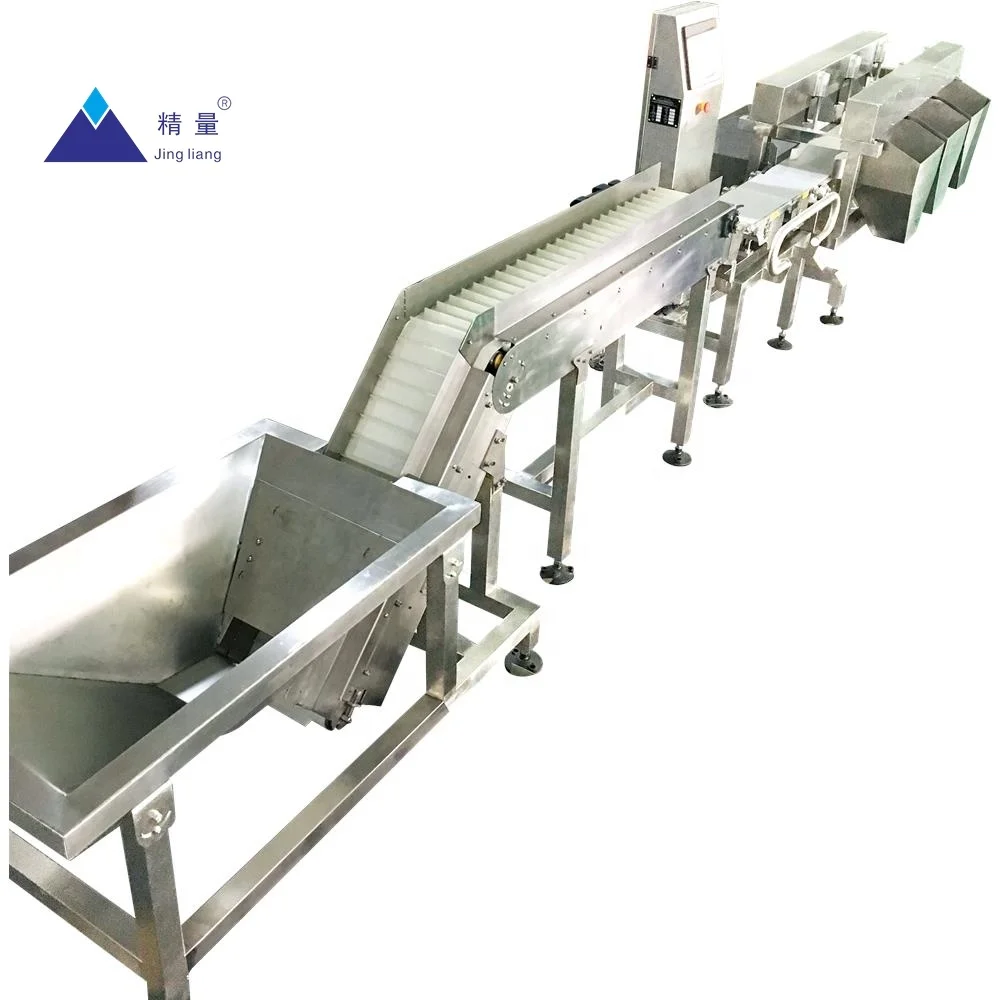

Weighing items on a conveyor belt can be complex depending on your inputs, as there are different input types from bulk solids to granules and powders, and they can vary in speed. Some weighers are more efficient for the lightest ones, while others are for heavier ones. Moreover, make sure to verify the accuracy of the weigher, and whether or not it can be adjusted to your needs. Many industrial applications have different types of conveyor belt weighers from Jing Liang.

Regular maintenance and adjustment is essential to obtaining accurate results from your conveyor belt weigher. At this point, it can involve cleaning the sensors, inspecting for damage and calibrating the weigher to ensure accuracy. MaintenancePackageCheckupRegular care helps avoid errors, keep the production process unaffected by miscommunications, and therefore avoid heading to emergency repair ministry. Jing Liang provides maintenance and adjustment for conveyor belt weighers to accurately and efficiently record production in companies.

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.