When we know how a belt weigher works, we are able to measure things probably. Beltscale is a device that used to measures the flow from material on a belt system. It explains exactly how much something moves from one point to another. This is very handy in many jobs where they need to measure out materials carefully.

TEMP loaded as a belt weigher for collecting a certain amount of flow, an important sampling for accurate measurement. This forces us to make more informed decisions because we understand exactly how much material is being displaced. When we transfer ingredients to make candy, we must know how much of each ingredient. The sugar candy might not taste good if we use too much or too less. Now we can ensure every processor uses the induction of each input (Raw Material) as required with a belt weigh scales.

The belt weigher will save time and money. Reducing waste knowing how much material is being move When we use more material than we need, we lose money. If we are using too much, we may need to pause in order to get more materials. By entering the correct quantity of material with a belt check weigher, we can use the most optimal amount of processing materials at all times, saving time and money.

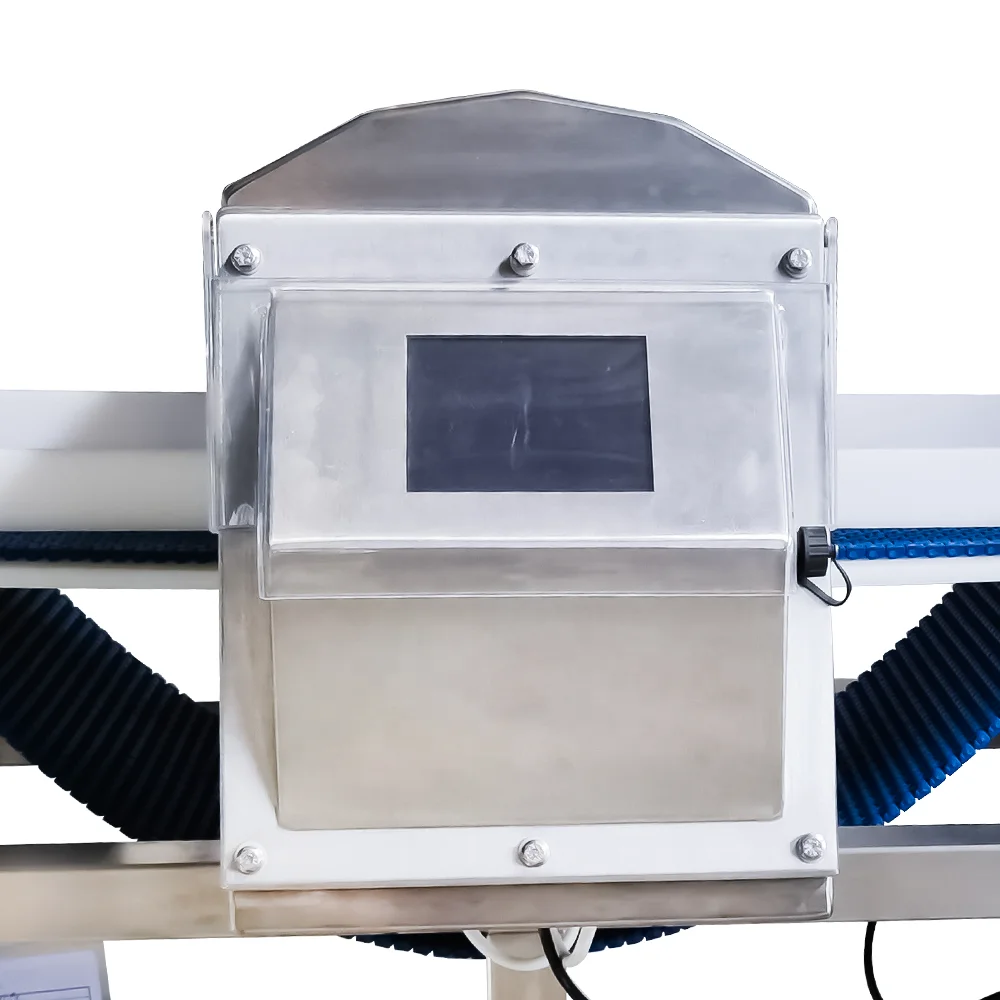

The belt weighers are meant for different types of jobs. For example some are better for heavy materials, and others for lighter materials. To obtain the best measurements, using the most appropriate type of belt weigher for the task is crucial.

A belt weigher can improve your quality of products in you work. You build better products when you have correct measurements. You can be certain that every time you are using the right amount of materials by using a belt checkweigher scale. It can help your products to be better quality and more consistent.

The 2,000 ㎡ of production manufacturing workshop, with advanced manufacturing, processing equipment, a number of professional and technical workers, own cutting machine, laser machine, grinding, etc., ensuring reliable production capacity. We offer ODM and OEM customized services

We possess 90% self-produced products, allowing us to control costs from the source. Our customers are all over the world, USA, Italy, France, Australia and so on. We have 20 years of manufacturing experience in checkweigher, sorting machine, metal detector,X-ray machine and so on.

Using an ERP system, we systematically manage production, Ensuring timeliness from order to shipment to meet the diversified needs of customers,achieve rapid development output.

We are standardized process management. We have a professional quality inspection team and testing equipment, from raw materials to finished products for comprehensive testing, ensuring product performance and environmental compliance.