Les machines détecteurs de métaux sont très critiques pour l'industrie alimentaire. L'entreprise Jing Liang produit des détecteurs de métaux de haute qualité, utilisés pour garantir la sécurité et l'hygiène des aliments. Ces Jing Liang détecteur de métaux pour l'industrie alimentaire transforment la manière dont les aliments sont produits et protègent la sécurité des personnes.

Il est très important de détecter les métaux présents dans les aliments. Des machines de balayage comme celles-ci peuvent localiser des objets métalliques dans les denrées alimentaires, ce qui permet d'assurer efficacement la sécurité des personnes. Les détecteurs de métaux Jing Liang sont extrêmement sensibles et capables de repérer même les plus petites particules métalliques, garantissant ainsi la sécurité des aliments.

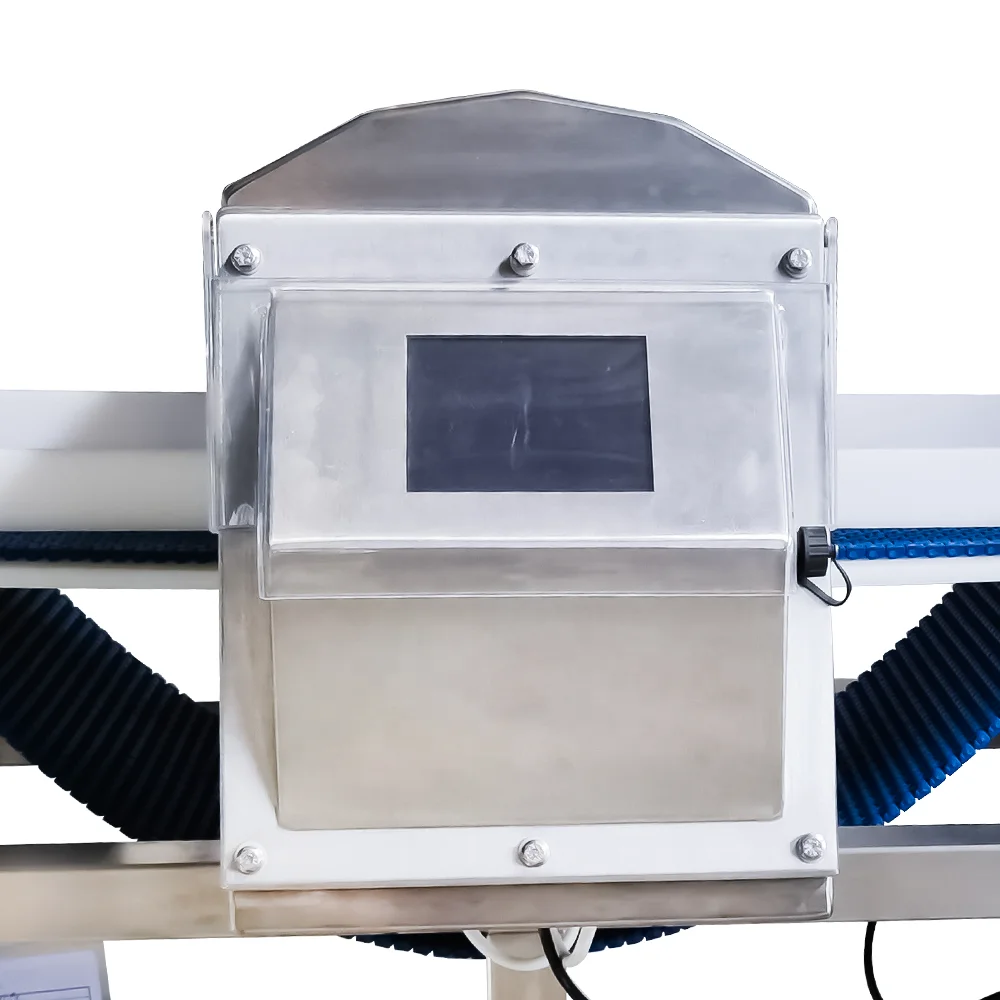

Les détecteurs de métaux contribuent également à rendre la production alimentaire plus rapide et plus pratique. Le processus d'inspection peut rapidement identifier les éclats métalliques dans les aliments, ce qui permet aux entreprises agroalimentaires d'économiser du temps et de l'argent. Jing Liang détecteur de métaux pour l'alimentation sont faciles à utiliser et peuvent être intégrés facilement dans les lignes de production existantes, ce qui en fait la solution idéale pour toute entreprise agroalimentaire.

L'entreprise Jing Liang a une grande ambition : garantir la sécurité des personnes grâce aux meilleurs détecteurs de métaux. Ces appareils sont capables de détecter différents types de métaux, notamment le fer, l'aluminium et l'acier inoxydable, afin de rendre les aliments sûrs à consommer. Les fabricants d'aliments peuvent utiliser ces Jing Liang détecteurs de métaux pour la transformation alimentaire pour s'assurer que leurs produits sont sûrs — et ainsi gagner la confiance des clients.

La détection de métaux dans la production alimentaire est un processus extrêmement important. Ces Jing Liang détecteur de métaux industrie agroalimentaire aident à préserver la sécurité des aliments et à éviter les blessures. Les détecteurs de métaux Jing Liang sont conçus pour durer et fabriqués avec une qualité supérieure, ce qui en fait une solution fiable pour les fabricants d'aliments souhaitant offrir une qualité.

L'atelier de fabrication de 2 000 m², avec des équipements avancés de fabrication et de traitement, dispose de nombreux travailleurs qualifiés et techniques, de machines de découpe, de machines laser, d'affûtage, etc., garantissant une capacité de production fiable. Nous offrons des services de personnalisation ODM et OEM.

Nous disposons de 90 % de produits autofabriqués, ce qui nous permet de contrôler les coûts à la source. Nos clients sont répartis dans le monde entier, aux États-Unis, en Italie, en France, en Australie, etc. Nous avons 20 ans d'expérience dans la fabrication d'équipements tels que les peseurs automatiques, les trieurs, les détecteurs de métaux, les machines à rayons X, etc.

En utilisant un système ERP, nous gérons systématiquement la production, en assurant la ponctualité de la commande à l'expédition pour répondre aux besoins diversifiés des clients et réaliser une sortie de développement rapide.

Nous sommes une gestion de processus standardisée. Nous disposons d'une équipe professionnelle d'inspection qualité et d'équipements de test, de la matière première au produit fini pour des tests complets, garantissant les performances des produits et leur conformité environnementale.