Dinamiese Weegmasjiene: Hierdie masjiene kontroleer en weeg produkte terwyl hulle deur die produksielyn beweeg. Soos baie intelligente weegskaale wat onmiddellik en presies 'n voorwerp kan weeg. Soortgereguleerde masjiene is cruciaal in verskeie bedrywe en om seker te stel dat die gewig van goedeware akkuraat is voordat hulle verpakt en gestuur word na klante.

Hulle doen dit met dinamiese weegkontrolesysteme om vervaardigingslyne te verbeter. Deur produkte vinnig te weeg terwyl hulle voorbypass, kan hierdie Weegkontrolesysteem masjiene enige items wat oor- of ondergewig opspoor. Dit laat maatskappye toe om op die vlug aan te pas en verseker dat elke produk regweg is. Dit spaar tyd en skuif afval om kostbare foute te vermy.

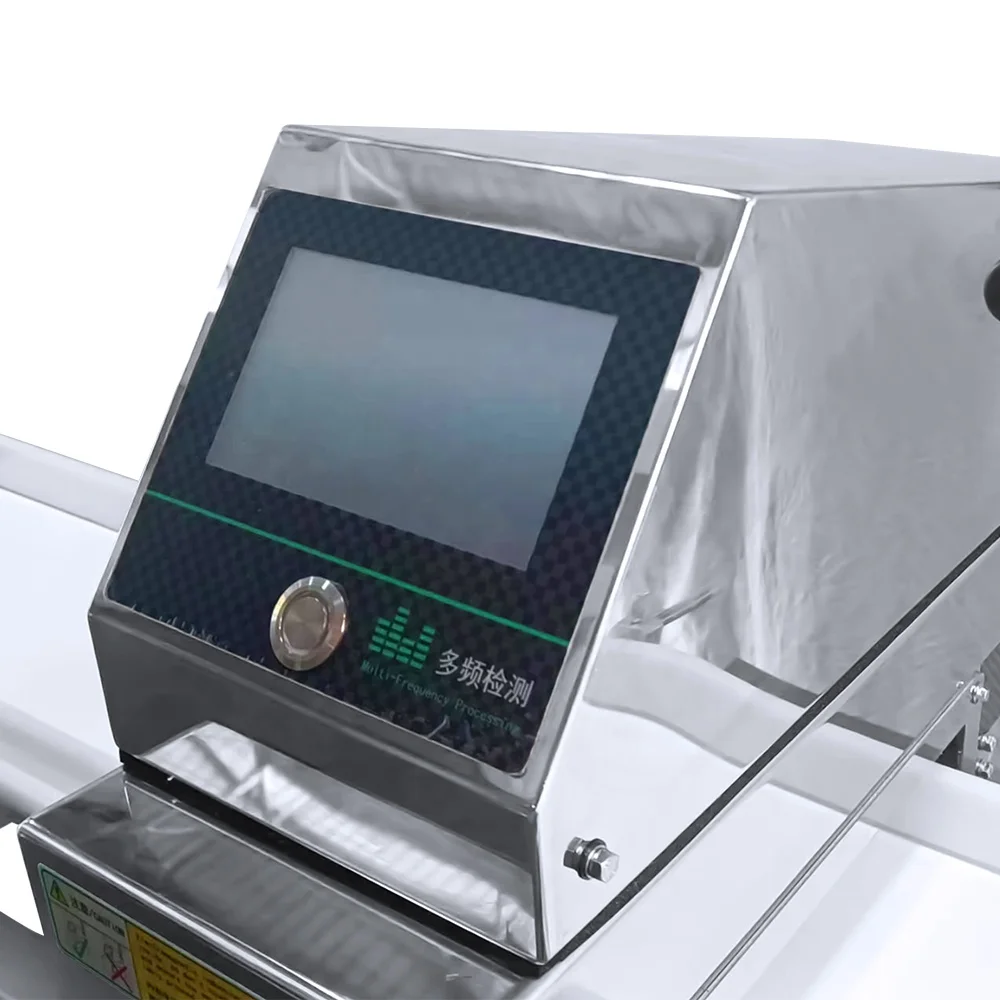

Dinamiese weegmachines moet baie akkuraat wees. Sulke masjiene moet hoogs presies wees om produkte akkuraat te weeg. 'n Klein fout kan daartoe lei dat produkte broos is of met die verkeerde gewig ingepak. Dit kan die reputasie van 'n maatskappy skade en finansiële verliese veroorsaak. Daarom, of 'n onderneming hoë kwaliteit nodig het, moet hulle 'n goeie dinamiese weegmachine hê, soos Jing liang en so meer.

Dinamiese weegmachines het 'n aantal uitstekende voordele om as kwaliteitsbeheer te funksioneer. Hierdie masjiene verseker dat die produkte die korrekte gewig het. Enige foute in die inpakking en probleme in die produksieproses kan ook deur hulle opgespoor word. Deur sulke probleme vroeg tydens te identifiseer, kan maatskappye slegte produkte voorkom om by klante te kom en duur herroeping koste vermy. Boonop Jing liang dinamies weegskaal-kontrole help dit maatskappye om ooreenstemming met bedryfsregulasies en standaarde te behaal en al die produkvereistesings te voldoen.

'n Dinamiese weegoplossing kan besighede in verskeie maniere meer laat verdien. Hierdie masjiene help om afval te verminder deur seker te stel dat elke item korrek geweeg word. Dit verhoog doeltreffendheid. Dinamies weegband dEUR Jing liang kan ook arbeidskoste verminder deur die weegproses te outomatiseer, wat werknemers vry maak om op ander aspekte van produksie te fokus. 'n Soortgereguleerde en energiebesparende dinamiese weegmasjiene kan lei tot verbeterde produktiwiteit, kwaliteitsbeheer en wins vir maatskappye.

Ons is gestandaardiseerde prosesbestuur. Ons het 'n professionele kwaliteitsinspekteerteam en toetsingsuitrusting, van grondstowwe tot eindprodukte vir omvattende toetsing, om produkprestasie en omgewingsvereenwoordigheid te verseker.

Die 2,000 m² produksiewerkswinkel, met gevorderde vervaardigings- en verwerkingsuitrustings, 'n aantal professionele tegniese werkers, besit sny masjiene, laser masjiene, polsteene ens., verseker betroubare produksiekapasiteit. Ons bied ODM en OEM aangepaste dienste.

Deur 'n ERP-stelsel te gebruik, bestuur ons produksie sistematies, verseker tydige levering vanaf bestelling tot versending om die gevarieerde behoeftes van klante te voldoen en vinnige ontwikkelingsuitsette te bereik.

Ons besit 90% self-geprodukteerde produkte, wat ons in staat stel om koste vanaf die bron te beheer. Ons kliënte is oor die hele wêreld, USA, Italië, Frankryk, Australië en so voort. Ons het 20 jaar vervaardigingservaring in weegmasjiene, sorteerapparate, metaaldetektors, röntgenmasjiene en so meer.